航空发动机为飞机提供飞行所需动力,民用主要有两种类型:活塞式发动机和喷气式发动机。

Aero-engines provide aircraft with the power required for flight. There are two main types of civil engines: piston engines and jet engines.

1、活塞发动机

Piston engine

活塞发动机主要为吸入空气,与燃油混合后点燃膨胀,驱动活塞往复运动,再转化为驱动轴的旋转输出。单单一个活塞发动机发出的功率非常有限,因此人们将多个活塞发动机并联在一起,组成星型或 V 型活塞发动机。活塞航空发动机用于带动螺旋桨或旋翼。大型活塞式航空发动机的功率可达 2500 千瓦,后来被功率大、高速性能好的燃气涡轮发动机所取代,但小功率的活塞式航空发动机仍广泛地用于轻型飞机、直升机及超轻型飞机。

The piston engine mainly absorbs air, ignites and expands after mixing with fuel drives the piston to reciprocate, and then converts it into the rotating output of the drive shaft. The power generated by a single piston engine is very limited; so many piston engines are connected in parallel to form a star or V piston engine. Piston aero engines are used to drive propellers or rotors. The power of large piston aero-engine can reach 2500 kW, which was later replaced by the gas turbine engine with high power and high speed performance. However, the piston aero-engine with small power is still widely used in light aircraft, helicopters and ultra-light aircraft.

(1)活塞发动机的结构与工作原理

Structure and working principle of piston engine

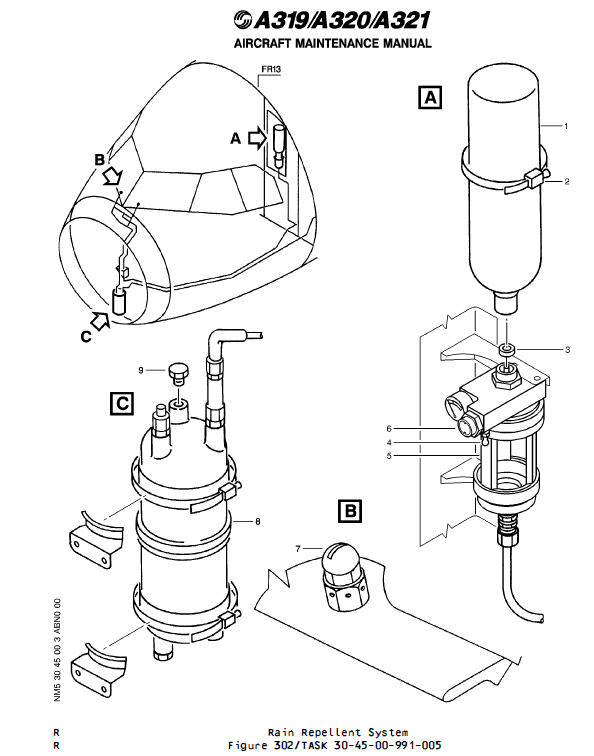

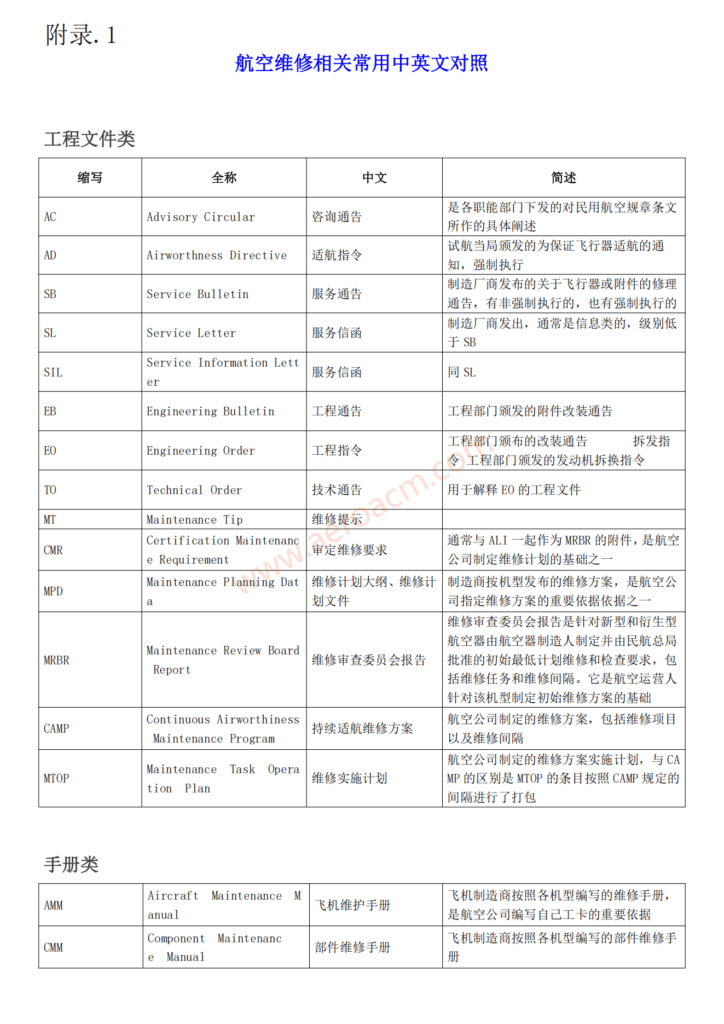

航空活塞式发动机的基本构件是汽缸和活塞曲轴和连杆。汽油在气缸中燃烧,形成高温气体,气体膨胀作功,推动活塞在汽缸中向下运动,活塞带动连杆,连杆连在曲轴上,使曲轴转动,曲轴继续转动,使活塞又向上移动,然后,再开始点火,使活塞再向下运动,这样往复不断,就把汽油燃烧的热能转化为曲轴转动的机械能,这就是活塞式发动机最基本的工作原理。为实现这一过程,发动机的动作由四个过程构成一个循环,我们称这个过程为冲程(如图 1 所示)。发动机每进行一次循环,活塞往复两次,经过四个冲程,因此这种发动机被称做四冲程发动机,也被称做往复式发动机,在调控机构的调控下,一个循环接着一个循环的工作下去,发动机就连续工作了。

The basic components of aviation piston engine are cylinder, piston, crankshaft and connecting rod. Gasoline burns in the cylinder to form high-temperature gas. The gas expands to work, pushing the piston to move downward in the cylinder. The piston drives the connecting rod. The connecting rod is connected to the crankshaft, making the crankshaft rotate. The crankshaft continues to rotate, making the piston move upward again. Then, the ignition starts again, making the piston move downward again. In this way, the heat energy of gasoline combustion is converted into mechanical energy of crankshaft rotation; This is the basic working principle of piston engine. To realize this process, the engine action consists of four processes forming a cycle, which we call the stroke (as shown in Figure 2.5-2). Every time the engine performs a cycle, the piston reciprocates twice and passes through four strokes. Therefore, this engine is called a four-stroke engine, also known as a reciprocating engine. Under the control of the regulatory agency, the engine will continue to work one cycle after another.

![图片[1]-航空发动机的种类-活塞式和喷气式发动机 Types of Aero-Engine-Piston and Jet Engines【转】-航修札记](https://www.aeroacm.cn/wp-content/uploads/2025/07/image-17.png)

活塞式发动机用单个气缸功率是不够的,因为汽缸通常由于材料强度的限制不能做的太大,一个气缸的工作也不均衡,因而震动很大,发动机都作成是多气缸的,多汽缸的工作时间错开就使得振动变的均匀,功率越大,气缸就越多,一般航空发动机都在 5 缸以上,最多 28 缸,功率达到 4000 马力。人们将多个活塞发动机并联在一起,组成星型或 V 型活塞发动机。

The power of a single cylinder is not enough for a piston engine, because the cylinder can not be too large due to the limitation of material strength, and the work of a cylinder is not balanced, so the vibration is large. The engine is made of multi cylinder, and the staggered working time of multi-cylinder makes the vibration uniform. The greater the power, the more cylinders. Generally, the aero-engine is more than 5 cylinders, with a maximum of 28 cylinders and a power of 4000 horsepower. Many piston engines are connected in parallel to form a star or V piston engine.

发动机要工作要有燃料系统,它由油箱、导管和进气系统组成,进气系统有汽化器式和直接喷射式两种,汽化器使燃油雾化,在气缸外与空气混合再进入气缸;直接喷射系统中燃油通过喷射装置直接进入气缸,在气缸内与空气混合。混合气的点燃要有点火系统,点火系统由产生高压电的磁电机和点火分配器和火花塞组成,磁电机产生的高压电通过分配器按顺序时刻分送到各个气缸的火花塞,火花塞及时发出电火花点燃混合气体。为了减少机件之间的摩擦阻力,发动机配有润滑系统,润滑系统由滑油箱、滑油泵和管道组成,滑油通过滑油泵被强制送到各个摩擦面上去润滑这些接触面,减少摩擦阻力。然后流回滑油箱。发动机由于在工作中积累的热量而不断升温,因而必须有冷却系统,使工作温度保持正常,冷却系统有两类,一种是液冷式,它用气缸外流动的冷却液(一般是水)来吸收热量,然后冷却液在散热器上由迎面来的气流带走热量,这种冷却方式的优点是发动机截面可以做的比较小,阻力较小,但结构复杂重量增加;另一种是气冷式,这种发动机的气缸外壁上有很多散热片,气缸迎风成星形布置,迎面气流吹过散热片带走热量,这种发动机为了提高冷却效率,迎风面积要较大,阻力增大,但结构较轻。现代的活塞发动机以气冷式较多。此外活塞发动机从静止状态启动需要有外部的力量推动,最早期的航空发动机也有像早期汽车一样人力启动,现代的航空发动机都装有启动系统,启动系统也有两种,一种是气动的,用压缩气体充入气缸使发动机启动,另一种是电动的,使用一个启动电动机带动启动机使曲轴旋转。有了以上各种系统的配合,航空活塞发动机就可以正常工作了。

The engine should have a fuel system to work, which is composed of fuel tank, duct and air intake system. The air intake system has two types: carburetor type and direct injection type. The carburetor atomizes the fuel and mixes it with air outside the cylinder before entering the cylinder; In the direct injection system, the fuel enters the cylinder directly through the injection device and mixes with the air in the cylinder. The ignition system for the ignition of the mixture is composed of a magneto that generates high voltage electricity, an ignition distributor and a spark plug. The high voltage electricity generated by the magneto is sent to the spark plug of each cylinder in sequence at all times through the distributor. The spark plug sends out an electric spark in time to ignite the mixture. In order to reduce the friction resistance between parts, the engine is equipped with a lubrication system, which is composed of oil tank, oil pump and pipeline. The oil is forced to lubricate these contact surfaces through the oil pump to reduce the friction resistance. Then it flows back to the oil tank. The engine is constantly warming up due to the heat accumulated in the operation, so there must be a cooling system to keep the operating temperature normal. There are two types of cooling systems. One is liquid-cooled. It uses the coolant flowing outside the cylinder (usually water) to absorb the heat, and then the coolant carries the heat away from the heat exchanger by the air flow coming from the front. The advantage of this cooling method is that the engine section can be made smaller and the resistance is smaller, However, the structure is complex and the weight is increased; The other is air-cooled type. There are many fins on the outer wall of the cylinder of this engine. The cylinder is arranged in a star shape in the windward direction. The air flow blows through the fins to take away the heat. In order to improve the cooling efficiency, the windward area of this engine is larger, the resistance is increased, but the structure is lighter. Modern piston engines are mostly air-cooled. In addition, piston engines need to be driven by external forces to start from a static state. The earliest aero-engines also have the same manual starting as early automobiles. Modern aero-engines are equipped with starting systems. There are also two kinds of starting systems. One is pneumatic, which uses compressed gas to fill the cylinder to start the engine, and the other is electric, which uses a starting motor to drive the starter to rotate the crankshaft. With the cooperation of the above systems, the aviation piston engine can work normally.

![图片[2]-航空发动机的种类-活塞式和喷气式发动机 Types of Aero-Engine-Piston and Jet Engines【转】-航修札记](https://www.aeroacm.cn/wp-content/uploads/2025/07/image-18.png)

(2)螺旋桨

Propeller

活塞式发动机单独不能驱动飞机,它必须驱动螺旋桨才能使飞机运动,因而活塞发动机和螺旋桨在一起才构成了活塞式飞机的推进系统。飞机的螺旋桨有 2-6 个叶片组成,每个单独的叶片从根部到顶部扭曲,它的每一个与叶片轴线垂直的截面都相当机翼的一个翼型。当它相对于空气转动时,把空气向后排开,空气的反作用力如同机翼的情况一样,在剖面突出的一边空气流动快,压力小;在剖面呈直线的一边空气流动慢,压力大,这个压差形成了垂直于桨叶叶面的力,但是桨叶的运动平面和飞机的纵轴垂直,因而在螺旋桨的一侧会产生和飞机纵轴平行的拉力。和机翼一样桨叶的叶弦相对于迎面的气流的角度是迎角,迎角的大小,影响着拉力的大小。随着飞行速度的提高,螺旋桨翼面的合成速度向叶弦靠拢,使迎角变小,这样拉力就会减小,这时如果能使桨叶角变大,则螺旋桨的迎角就会增大到原来的有利状态,因而就产生了变距螺旋桨。当不需要螺旋桨产生拉力时(降落或发动机失效),为减少阻力可以使迎角调为 0,桨叶将顺着气流旋转,也叫顺桨,这时的阻力最小。也可以使桨叶角变为负值,使螺旋桨产生反方向的拉力,阻止飞机前进,这时称为反桨,以利于飞机在着陆时缩短降落距离(如图 2 所示)。变矩螺旋桨能在飞行的各种状态下,桨距按照具体的需要进行调节,这样发动机和螺旋桨充分发挥了效率,也保证了发动机和螺旋桨能在转速不变的情况下,改变桨距来适应飞行速度改变时对力矩的需要。

The piston engine alone cannot drive the aircraft. It must drive the propeller to make the aircraft move. Therefore, the piston engine and the propeller together constitute the propulsion system of the piston aircraft. The propeller of the aircraft is composed of 2-6 blades. Each individual blade is twisted from the root to the top. Each section perpendicular to the blade axis is equivalent to an airfoil of the wing. When it rotates relative to the air, it pushes the air backward, and the reaction force of the air is the same as that of the wing. The air flows fast and the pressure is small on the protruding side of the profile; The air flow is slow and the pressure is high on the straight side of the profile. This pressure difference forms a force perpendicular to the blade surface, but the motion plane of the blade is perpendicular to the longitudinal axis of the aircraft, so a pull parallel to the longitudinal axis of the aircraft will be generated on the side of the propeller. Like the wing, the angle of the chord of the blade relative to the upstream airflow is the angle of attack. The angle of attack affects the pull force. With the increase of flight speed, the resultant speed of the propeller wing surface is close to the chord, making the angle of attack smaller, so that the pull force will be reduced. At this time, if the angle of attack of the propeller can be increased, the angle of attack of the propeller will increase to the original favorable state, and thus the variable pitch propeller is produced. When there is no need for the propeller to generate tension (landing or engine failure), the angle of attack can be adjusted to 0 to reduce the resistance, and the blade will rotate along the airflow, also known as feathering, at which time the resistance is the minimum. It can also change the blade angle to a negative value and make the propeller produce a pull force in the opposite direction to prevent the aircraft from moving forward, which is called reverse propeller, so as to shorten the landing distance of the aircraft during landing (as shown in Figure 2). Torque change propeller can adjust the pitch according to the specific needs under various flight conditions, so that the engine and propeller can give full play to the efficiency, and also ensure that the engine and propeller can change the pitch to adapt to the torque requirements when the flight speed changes with the same speed.

(3)活塞发动机的性能特点

Performance characteristics of piston engine

航空活塞发动机的性能指标,除了功率、重量等直接指标外,评价它的性能好坏的有两个重要指标。一个是燃油消耗率,即每马力一小时内消耗的燃油重量,这个指标越低,说明这个发动机的经济性越好。另一个指标则是重量功率比,重量用公斤表示,功率使用马力。这个比值越低说明发动机重量轻而马力大。第一架飞机上的活塞发动机的重量马力比为 6.4 公斤/马力。而到 40 年代末达到 0.5 公斤/马力,耗油率也从 1 公斤/马力小时降到 0.2-0.25 公斤/马力小时,这个指标比喷气发动机低,所以在低速飞行时,活塞发动机的经济性能很好,活塞发动机在 50 年代初已经达到成熟期,工作可靠,大修期提高到 2000-3000 小时一次。因而它目前仍在小型、低速飞机和轻型直升机上广为应用。

In addition to power, weight and other direct indicators, there are two important indicators to evaluate the performance of aviation piston engine. One is the specific fuel consumption, that is, the weight of fuel consumed in one hour per horsepower. The lower this indicator is, the better the economy of the engine is. The other indicator is the ratio of weight to power. The weight is expressed in kilograms and the power is expressed in horsepower. The lower the ratio, the lighter the engine weight and the higher the horsepower. The weight to horsepower ratio of the piston engine on the first aircraft was 6.4 kg/horsepower. By the end of the 1940s, it had reached 0.5 kg/hp, and the specific fuel consumption had also decreased from 1 kg/hp to 0.2~0.25 kg/hp. This index was lower than that of jet engines. Therefore, when flying at low speed, the piston engine’s economic performance was very good. The piston engine had reached its mature stage in the early 1950s, and its work was reliable, and the overhaul period was increased to 2000~3000 hours. Therefore, it is still widely used in small, low-speed aircraft and light helicopters.

2、喷气发动机

Jet engine

喷气发动机通过吸入大量的空气,燃油在发动机内部的燃烧使燃料的化学能转化为机械能,燃烧后的气流高速喷出,把气体排向后方,气流对发动机产生反作用力,推动飞机向前飞行。喷气发动机既转换能量又产生推力,其本身就是一个推进系统。喷气式发动机目前应用比较广泛,主要有涡轮喷气发动机、涡轮风扇发动机、涡轮螺旋桨发动机和涡轮轴发动机。

The jet engine absorbs a large amount of air, and the combustion of fuel in the engine converts the chemical energy of fuel into mechanical energy. The gas after combustion is ejected at a high speed, and the gas is discharged to the rear. The air flow has a reaction force on the engine, pushing the aircraft forward. Jet engine not only converts energy but also generates thrust, and is itself a propulsion system. Jet engines are widely used at present, mainly including turbojet engines, turbofan engines, turboprop engines and turboshaft engines.

暂无评论内容