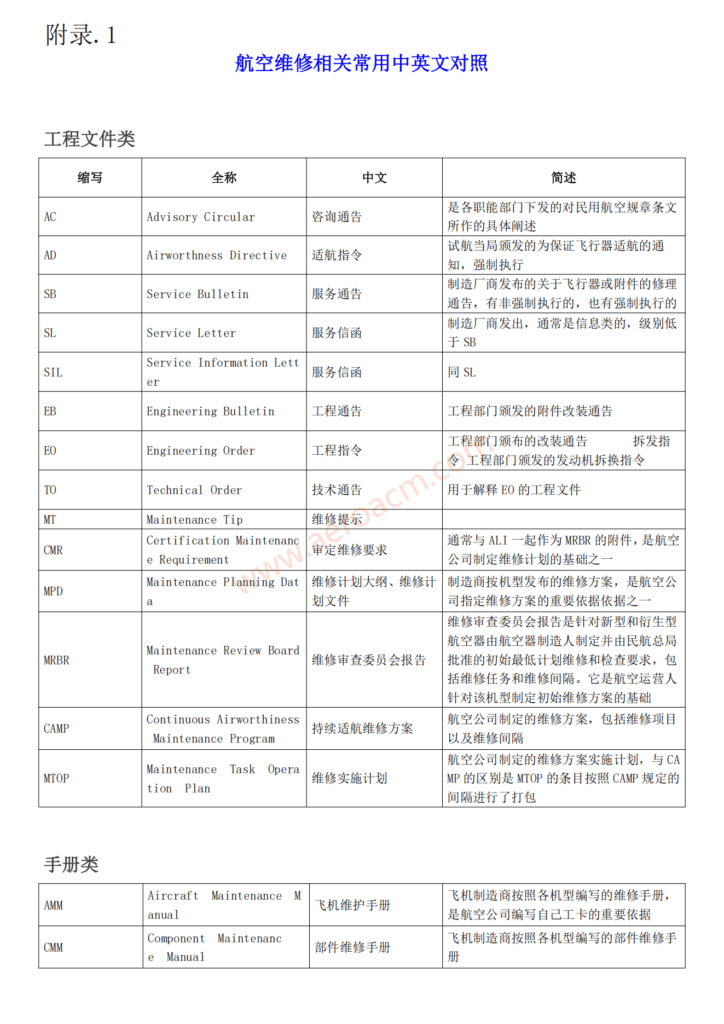

温度传感器

一、名称

PNEUMATIC TEMPERATURE SENSOR

气动温度传感器

二、件号

766A0000-01,766B0000-01,766C0000-01

三、章节号

21-52-28

四、适用机型

A318/A319/A320/A321/A330/A340

五、系统

21 AIR CONDITIONING

空调

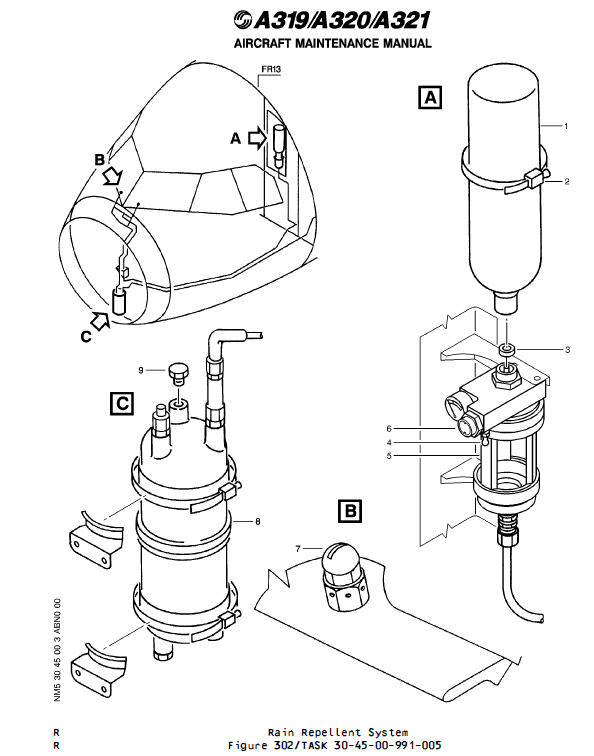

六、安装位置

空调舱

![图片[1]-766A/B/C PNEUMATIC TEMPERATURE SENSOR-航修札记](https://www.aeroacm.cn/wp-content/uploads/2025/07/word-image-8023-1.png)

![图片[2]-766A/B/C PNEUMATIC TEMPERATURE SENSOR-航修札记](https://www.aeroacm.cn/wp-content/uploads/2025/07/word-image-8023-2.png)

七、部件原理

General Description

The pneumatic temperature sensor is used on the Cooling Pack Air Conditioning System, and includes:

– an INVAR clapper rod inside a stainless steel housing and brazed to the bottom of the stick,

– a spring and screw adjusted to permit the clapper opening at the correct value,

– a filter union,

– a body.

基本描述

该气动温度传感器用于冷却PACK空调系统,pack括:

-不锈钢外壳内的INVAR阀杆(不胀钢阀杆)和钎焊在钢管杆的底部,

-弹簧和螺钉调节以允许阀杆在正确值打开,

-过滤器接头,

-壳体。

Detailed Description

The Pneumatic Temperature Sensor consists of:

– a temperature sensor stick made in INVAR metal clapper rod located inside a stainless steel tubular housing. The parts are brazed to the bottom of the stick,

– a drilled adjusting screw, used as a seat, allows the airflow passage section to be adjusted to the required value,

– a body which receives the stick, the adjusting screw, a threaded filter union (on inlet side) and a mesh filter fixed by a lock washer, a retaining ring, washer, and lockwire (on outlet side),

– a spring,

– a preformed packing to obtain tightness of adjusting screw in body mounting bore.

详细说明:

气动温度传感器由以下部件构成:

-由不锈钢INVAR阀杆(不胀钢阀杆)制成的温度传感棒,安装于不锈钢管杆内。各部件通过钎焊固定于不锈钢管杆底部;

-带孔调节螺钉作为阀座,可将气流通道调整至所需数值;

-壳体结构pack含传感棒、调节螺钉、带螺纹的过滤接头(入口侧)以及通过锁紧垫圈、卡环、垫圈和保险丝固定在出口侧的网状过滤器;-弹簧

-预成型密封件,确保调节螺钉与壳体安装孔之间的密封性。

![图片[3]-766A/B/C PNEUMATIC TEMPERATURE SENSOR-航修札记](https://www.aeroacm.cn/wp-content/uploads/2025/07/word-image-8023-3.png)

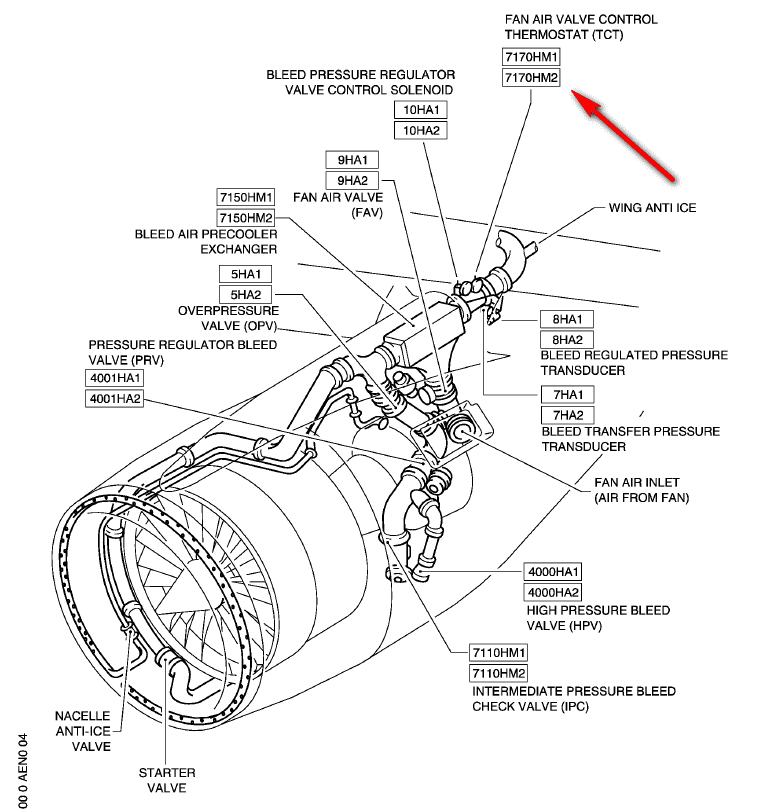

Operation

A. General operation (Refer to Figure 2)

The sensor is composed of a part sensitive to temperature: an INVAR clapper rod (very low expansion factor) inside a stainless steel housing (higher expansion factor). When opening, the clapper rod lets to vent the air from the valve actuator chamber to which the sensor is connected through a sense line.

操作

A.基本操作(Refer to Figure 2)

传感器由对温度敏感的部件组成:一个INVAR阀杆(极低膨胀系数)位于不锈钢外壳内(高膨胀系数)。当开启时,阀杆会将空气从活门执行器腔室排出,而传感器通过感应管与该腔室相连。

![图片[4]-766A/B/C PNEUMATIC TEMPERATURE SENSOR-航修札记](https://www.aeroacm.cn/wp-content/uploads/2025/07/word-image-8023-4.png)

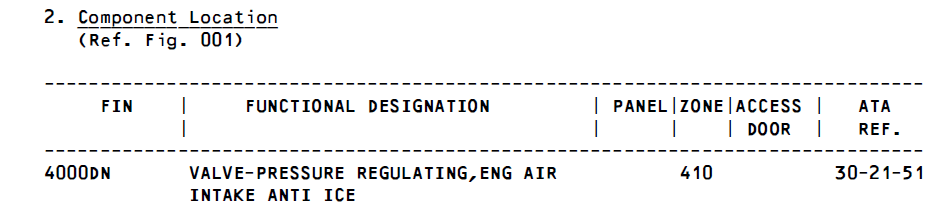

八、工作参数

![图片[5]-766A/B/C PNEUMATIC TEMPERATURE SENSOR-航修札记](https://www.aeroacm.cn/wp-content/uploads/2025/07/word-image-8023-5.png)

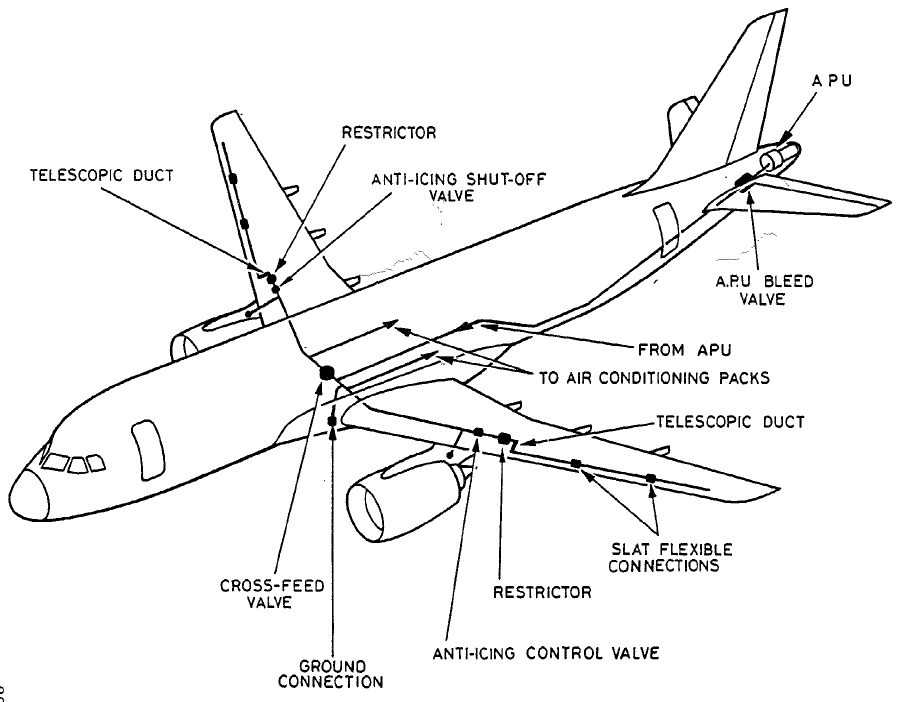

九、在系统中工作原理

The pneumatic compressor-overheat sensors 10HM9 (11HM9) are installed downstream of the compressors of the air-cycle machines 10HM1 (11HM1).They are connected to the flow control valves 8HB (11HB). If the compressor outlet temperature increases above a predetermined value (aprrox. 230 deg.C), the pneumatic compressor overheat-sensor gives a signal to reduce the airflow via the flow control valve.

气动压缩机过热传感器10HM9(11HM9)安装在空气循环机组10HM1(11HM1)的压缩机下游,与流量控制活门8HB(11HB)(964A/F)相连。当压缩机出口温度超过预设值(约230℃)时,该传感器会向流量控制活门发送信号,自动降低气流流量。

![图片[6]-766A/B/C PNEUMATIC TEMPERATURE SENSOR-航修札记](https://www.aeroacm.cn/wp-content/uploads/2025/07/word-image-8023-6.png)

System Description

During normal operation, the zone controller 8HK sends the required pack outlet temperature to the pack controllers 7HH (27HH). To get the pack outlet temperature, the pack controller modulates the bypass valve 10HH (30HH) and the ram-air inlet flaps in a predetermind sequence. This sequence is a compromise between a minimum ram airflow while maintaining adequate heat transfer rates and sufficient pack flow.

For maximum cooling, ram-air flaps are fully open and the bypass valve is fully closed.

For maximum heating, the ram-air flaps are nearly closed and the bypass valve fully open.

The bypass valve will ensure sufficient flow through the air-cycle machine to stop the speed falling below idle.During takeoff and landing, the ram air inlet flaps will be driven fully closed to stop the ingestion of foreign matter.

系统描述

在正常运行时,区域控制器8HK会向各pack控制器7HH(27HH)发送所需的pack出口温度指令。为获取该温度值,pack控制器需按照预设顺序调节旁通阀10HH(30HH)和冲压空气进气活门板。该操作流程是在平衡最小冲压空气流量与保持充分传热效率和pack流量需求之间达到平衡。

最大冷却模式下,冲压空气活门板全开且旁通活门完全关闭;

最大加热模式,则近乎关闭冲压空气活门板并开启旁通活门。

旁通活门能确保空气循环系统持续供气,防止转速低于怠速状态。在起飞和降落过程中,冲压空气进气活门板将被完全关闭以杜绝异物吸入。

![图片[7]-766A/B/C PNEUMATIC TEMPERATURE SENSOR-航修札记](https://www.aeroacm.cn/wp-content/uploads/2025/07/word-image-8023-7.png)

The compressor pneumatic overheat-sensor 10HM9 (11HM9) consists of a bi-metalic rod which is inserted into the hot airflow. The sensor is connected through a sensing line, to the flow control valve 8HB (11HB) shuttle valve assembly. It vents flow control muscle pressure to ambient (Ref. 21-51-00). Differential expansion in the rod will start to open the vent at 230 DEG.C (446.00 DEG.F) (any further increase in temperature will increase the opening area). The angle of the flow control valve is now controlled pneumatically, to stop an overheat of 260 DEG.C (500.00 DEG.F). The pneumatic sensor is located in the compressor discharge duct close to the compressor overheat sensor 15HH (35HH).

压缩机气动过热传感器10HM9(11HM9)由一根插入高温气流中的双金属棒构成。该传感器通过感应管与流量控制活门8HB(11HB)的梭阀组件相连,用于将流量控制作用压力释放至环境中(参考21-51-00)。当温度达到230摄氏度(446华氏度)时,棒体的热膨胀差值会触发排气阀开启(温度继续升高将扩大阀门开度)。此时流量控制活门的角度通过气动系统进行调节,可防止温度超过260摄氏度(500华氏度)。该气动传感器安装在压缩机排气管道内,紧邻过热传感器15HH(35HH)的位置。

![图片[8]-766A/B/C PNEUMATIC TEMPERATURE SENSOR-航修札记](https://www.aeroacm.cn/wp-content/uploads/2025/07/word-image-8023-8.png)

![图片[9]-766A/B/C PNEUMATIC TEMPERATURE SENSOR-航修札记](https://www.aeroacm.cn/wp-content/uploads/2025/07/word-image-8023-9.png)

![图片[10]-766A/B/C PNEUMATIC TEMPERATURE SENSOR-航修札记](https://www.aeroacm.cn/wp-content/uploads/2025/07/word-image-8023-10.png)

暂无评论内容