Sealing Compounds

密封化合物

Certain areas of all aircraft are sealed to withstand pressurization by air, to prevent leakage of fuel, to prevent passage of fumes, or to prevent corrosion by sealing against the weather. Most sealants consist of two or more ingredients properly proportioned and compounded to obtain the best results. Some materials are ready for use as packaged, but others will require mixing before application.

所有飞机的某些部位都设有密封结构,用于承受空气增压、防止燃油泄漏、阻隔烟雾渗透或抵御恶劣天气腐蚀。大多数密封胶由两种或多种成分按比例精确配制而成,以达到最佳效果。有些材料可以直接使用包装好的成品,而另一些则需要在使用前自行调配。

One Part Sealants

单组分密封胶

One part sealants are prepared by the manufacturer and are ready for application as packaged. However, the consistency of some of these compounds may be altered to satisfy a particular method of application. If thinning is desired, use the thinner recommended by the sealant manufacturer.

单组分密封胶由制造商制备,包装时已准备好应用。然而,其中一些化合物的稠度可能会改变,以满足特定的应用方法。如果需要稀释,请使用制造商推荐的稀释剂。

Two Part Sealants

双组分密封胶

Two part sealants are compounds requiring separate packaging to prevent cure prior to application and are identified as the base sealing compound and the accelerator. Any alteration of the prescribed ratios will reduce the quality of the material. Generally, two-part sealants are mixed by combining equal portions (by weight) of base compound and accelerator.

双组分密封胶是需要单独包装的化合物,以防止在应用前固化,并被确定为基本密封化合物和加速剂。对规定的比例的任何改变都会降低材料的质量。通常,双组分密封胶通过混合等量(按重量)的基本化合物和加速剂来混合。

All sealant material should be carefully weighed in accordance with the sealant manufacturer’s recommendations. Sealant material is usually weighed with a balance scale equipped with weights specially prepared for various quantities of sealant and accelerator.

所有密封材料应按照制造商的建议仔细称量。密封材料通常用天平称量,天平配有专门用于各种密封材料和加速剂重量的砝码。

Before weighing the sealant materials, thoroughly stir both the base sealant compound and the accelerator. Do not use accelerator which is dried out, lumpy, or flaky. Preweighed sealant kits do not require weighing of the sealant and accelerator before mixing when the entire quantity is to be mixed.

称量密封胶材料前,应充分搅拌基础密封胶化合物和加速剂。不要使用干燥、块状或片状的加速剂。当需要混合全部数量时,预先称量的密封胶套件不需要在混合前称量密封胶和加速剂。

After determining the proper amount of base sealant compound and accelerator, add the accelerator to the base sealant compound. Immediately after adding the accelerator, thoroughly mix the two parts by stirring or folding, depending on the consistency of the material. Carefully mix the material to prevent entrapment of air in the mixture. Overly rapid or prolonged stirring will build up heat in the mixture and shorten the normal application time (working life) of the mixed sealant.

确定好基础密封胶和加速剂的用量后,将加速剂加入基础密封胶中。加完加速剂后立即搅拌或折叠混合两种材料,具体操作方式取决于材料的稠度。注意充分搅拌防止空气夹带,但切忌过度快速或长时间搅拌,否则会导致混合物过热,缩短密封胶的正常施工时间(即工作寿命)。

To ensure a well mixed compound, test by smearing a small portion on a clean, flat metal or glass surface. If flecks or lumps are found, continue mixing. If the flecks or lumps cannot be eliminated, reject the batch.

为确保混合均匀,可取少量混合物在洁净平整的金属或玻璃表面上涂抹,如发现斑点或结块,继续混合,若仍不能消除,则报废该批次。

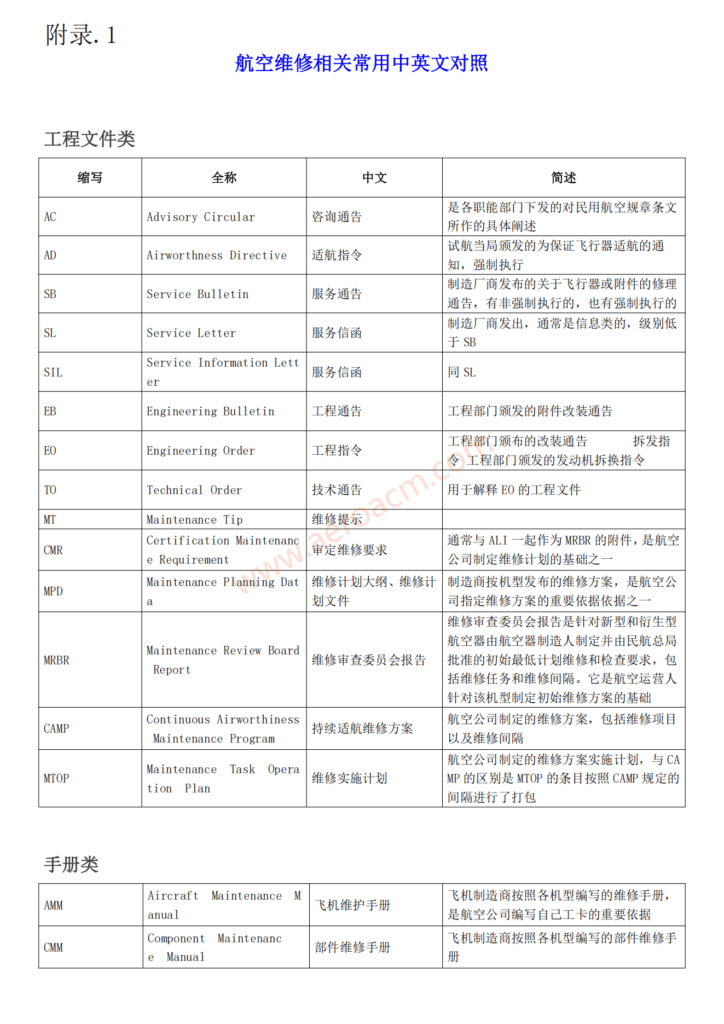

The working life of mixed sealant is from hour to 4 hours (depending upon the class of sealant); therefore, apply mixed sealant as soon as possible or place in refrigerated storage. Figure 5-18 presents general information concerning various sealants.

混合密封胶的工作寿命为1小时至4小时(取决于密封胶的类别);因此,应尽快使用混合密封胶或将其置于冷藏储存。图5-18显示了关于各种密封胶的一般信息。

The curing rate of mixed sealants varies with changes in temperature and humidity. Curing of sealants will be extremely slow if the temperature is below 60 °F. A temperature of 77 °F with 50 percent relative humidity is the ideal condition for curing most sealants.

混合密封胶的固化率会随温度和湿度的变化而变化,当温度低于60°F时,密封胶的固化速度会非常缓慢,77°F的温度和50%的相对湿度是大多数密封胶理想的固化条件。

Curing may be accelerated by increasing the temperature, but the temperature should never be allowed to exceed 120 °F at any time in the curing cycle. Heat may be applied by using infrared lamps or heated air. If heated air is used, it must be properly filtered to remove moisture and dirt.

可通过提高温度来加速固化,但固化周期内任何时候温度都不应超过120°F。可使用红外灯或加热空气进行加热。如果使用加热空气,则必须适当过滤以去除湿气和污垢。

Heat should not be applied to any faying surface sealant installation until all work is completed. All faying surface applications must have all attachments, permanent or temporary, completed within the application limitations of the sealant.

在所有工作完成之前,不得对任何接触表面密封胶安装进行加热。所有接触表面的应用必须在密封胶的使用限制范围内完成所有永久或临时附着。

Sealant must be cured to a tack-free condition before applying brush top coatings. (Tack-free consistency is the point at which a sheet of cellophane pressed onto the sealant will no longer adhere.)

在刷涂顶部涂层之前,密封剂必须固化到无粘性状态。(无粘性状态是指将玻璃纸压在密封剂上时,玻璃纸不再粘附的点。)

![图片[1]-Sealing Compounds-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/07/word-image-7811-1.png)

暂无评论内容