F. Gear and Spline Inspection

齿轮和花键检查

(1) Check gear and spline teeth as follows:

检查齿轮和花键齿,如下所示:

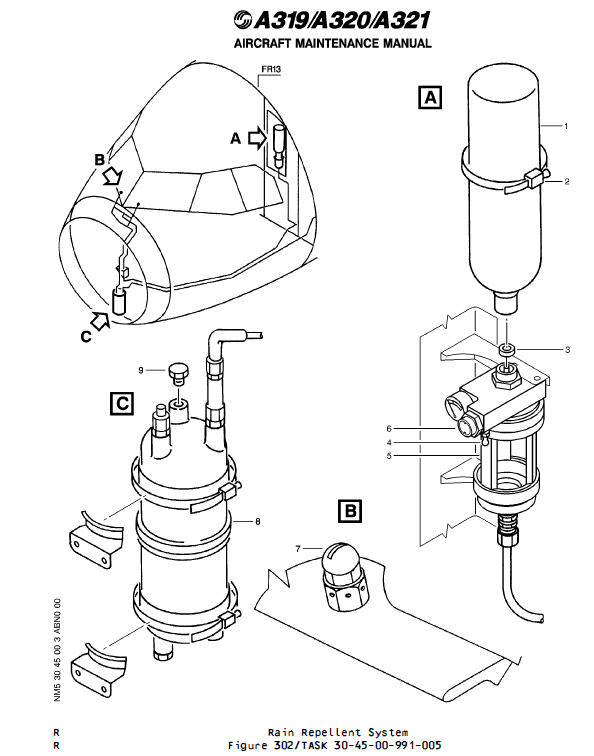

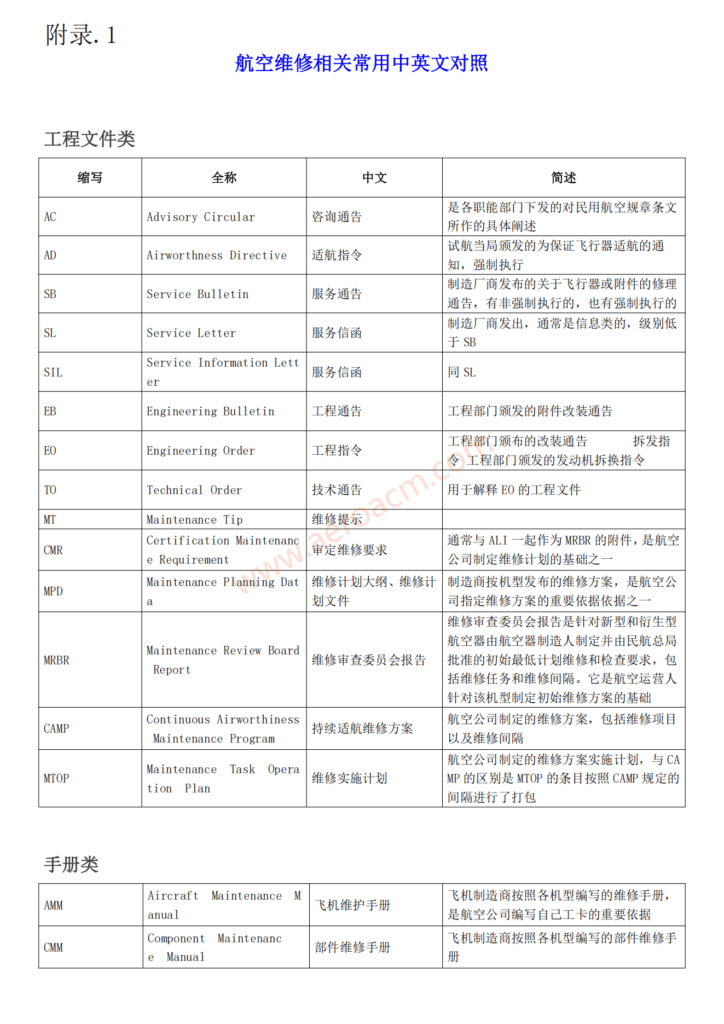

(a) Perform visual check using a strong light and a minimum of 5 times magnification. Refer to Figure 319 and Table 306 for typical examples of gear and spline wear.

使用强光和至少5倍的放大倍数进行目视检查。有关齿轮和花键磨损的典型示例,请参阅图319和表306。

(b) Visually check part for evidence of excessive spalling, fretting, surface flaking, chipping, splitting, rubbing, chafing, corrosion or other defects per Figure 319 and Table 306. If any of the defects specified are evident, replace part.

根据图319和表306目视检查零件是否存在过度剥落、微动磨损、表面剥落、碎裂、开裂、摩擦、擦伤、腐蚀或其他缺陷。如果存在任何规定缺陷,则更换零件。

(c) Visually check part for evidence of excessive corner loading. If wear pattern indicates corner loading of less than three-fourths of the normal length of tooth bearing contact area, replace part.

目视检查零件是否存在过度角载荷的迹象。如果磨损表明角载荷小于齿轴承接触区域正常长度的四分之三,则更换零件。

(d) Visually check part for evidence of metal displacement. If metal displacement is to the extent that sub-surface damage is probable, replace part.

目视检查零件是否存在金属位移的迹象(其实就是磨损)。如果金属位移可能造成次表面损坏,则更换零件。

NOTE: Healed scuffing of tooth involute surfaces is evidenced by a matted gray finish or localized burnished appearance, which usually results from wearing off raised metal. This condition is acceptable provided the scuffed area does not exceed 30 percent of the indicated pattern width, and the involute contour visually appears unaltered and no spalling or fretting exists.

注:齿形渐开线表面刮伤的愈合表现为亚光灰色表面或局部抛光外观,通常是由于凸起金属磨损所致。如果刮伤面积不超过指定花纹宽度的30%,且渐开线轮廓在视觉上没有变化,也没有剥落或磨损,则这种状况是可以接受的。

(e) Visually check part for evidence of healed scuffing of tooth involute surface.

目视检查零件,查看齿形渐开线表面已修复的刮伤情况。

NOTE: Magnetic Particle Inspection (MPI) is not required if the applicable IRM/EM provides an alternate inspection method (FPI, eddy current etc.) or specifically indicates MPI is not required.

注:如果适用的IRM/EM提供了替代检查方法(FPI、涡流等),或明确指出不需要MPI,则不需要进行磁粉探伤(MPI)。

(f) Check parts for cracks by performing magnetic particle inspection (SECTION III). No cracks are permissible.

通过执行磁粉检测(第三章)检查零件是否有裂纹。不允许有任何裂纹。

(g) Visually check part for evidence of overheating discoloration. If overheating discoloration of metal is evident, replace part, unless otherwise noted in applicable manual containing inspection criteria for the part.

目测零件是否有过热变色迹象。如果金属过热变色明显,则应更换零件,除非包含零件检查标准的适用手册中另有说明。

(h) Visually check teeth for evidence of abnormal or deep wear patterns. If visual check reveals abnormal or deep wear patterns, dimensionally check part by measuring gear teeth, over or between, pins or balls, placed in wear area, in accordance with applicable manual, containing inspection criteria for the part.

目测检查齿轮是否有异常或深度磨损的迹象。如果目测检查发现异常或深度磨损的迹象,则根据包含零件检查标准的适用手册,测量磨损区域中齿轮齿、销子或滚珠的尺寸。

(i) If overheating discoloration is evident, check gear hardness as specified in applicable manual to determine if gear is acceptable for further use.

如果过热变色很明显,则根据适用手册的规定检查齿轮硬度,以确定齿轮是否可以继续使用。

(j) Refer to applicable manual for wear limits of splines.

参阅适用手册,了解花键的磨损极限。

![图片[1]-SECTION III – INSPECTION 检查(三)之齿轮和花键检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/07/word-image-7771-1.png)

Table 306. Gear and Spline Teeth Physical Conditions 表 306. 齿轮和花键齿的物理状态 | ||

Term 术语 | Definition 定义 | Probable Cause 可能的原因 |

Broken 断裂 | Missing piece or pieces of a part. 零件缺失 | Careless handling. 处理不当 |

Chipped 缺口(碎片) | Missing piece or pieces of a part. 零件缺失 | Careless handling. 处理不当 |

Cracked 裂纹 | A partial failure 局部失效 | Excessive stress due to shock, overloading or faulty processing; extension of a nick or scratch;defective material; overheating. 冲击、过载或加工不当导致的过度应力;刻痕或划痕的延伸;材料缺陷;过热。 |

Frosted 磨砂 | Appearance of micropitting. Normal wear pattern appears frosted; the normal polish of surface has an etch- like finish: under magnification, the surface appears to be a field of very fine micro-pits less than 0.0001 in. (0.00254 mm) deep. 微点蚀的外观。正常磨损现象呈现磨砂状;表面的正常抛光呈现蚀刻状:放大后,表面呈现由深度小于0.0001英寸(0.00254毫米)的极细微坑组成的区域。 | Excessive heat generation in the gear mesh, from marginal lubrication. 由于润滑不足,齿轮啮合时产生过多热量。 |

Pitted 凹坑 | Surface fatigue characterized by small pits of 0.015 in. (0.38 mm) deep. 表面疲劳的特征是出现0.015英寸(0.38毫米)深的小凹坑。 | Material has gone past it’s endurance limit. 材料已达到其极限。 |

Scored 刮伤 | Radial gear marks on tooth wear pattern, which are produced by metal- to-metal contact. 径向齿轮磨损现象上的刮伤,由金属与金属接触产生。 | Excessive heat generation in the gear mesh that causes lubrication breakdown, which produces metal-to-metal contact. 齿轮啮合中产生过多热量,导致润滑失效,从而产生金属与金属的接触。 |

暂无评论内容