E. Bearing Inspection

轴承检查

(1) Separable Bearings:

可分解的轴承。

|

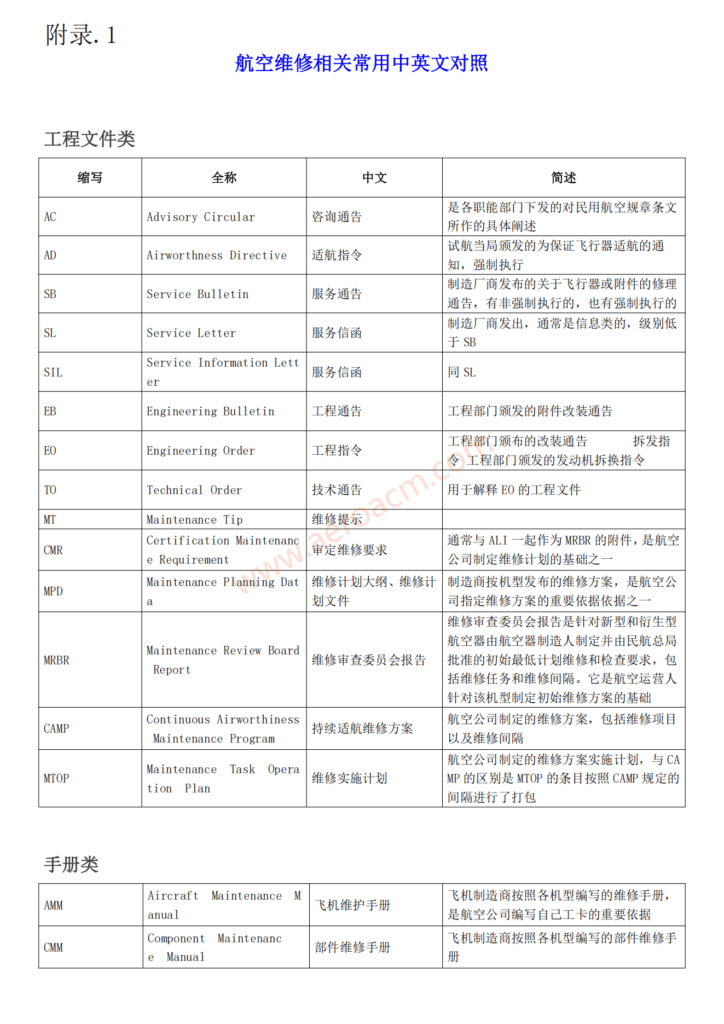

Table 301. Separable Bearing Defect Definitions 表301 可分解轴承缺陷的定义 |

|

|

Term 项目 |

Definition (Description of Defect) 定义(缺陷的描述) |

|

Arced 弧光 |

Round pit shaped cavity in a surface from which metal has been removed by electrical arc causing a temper change (softer) in the metal around the pit shaped cavity. It may be caused by a lightning strike or similar electrical occurrence. 在金属表面被电弧除去的圆形坑状空腔,使坑状空腔周围的金属发生回火变化 (软)。可能是电击或类似的电气事故引起的。 |

|

Bent 弯曲 |

Deformed from original shape or form . An example would be cages that are deformed from improper installation or bearing wear. 原来的形状或形态发生变形,如保持器因为不正确的安装或轴承磨损导致的变形。 |

|

Brinelling (True) 冲击腐蚀 |

True brinelling is plastic flow of metal, characterized by smooth shiny bottomed indentations in raceways or rolling elements usually equally spaced corresponding to rolling element spacing. Caused by impact, improper installation/removal or dropping of the bearing or unit it is installed in. (Refer to Figure 309) 冲击腐蚀是金属的塑性流动,特征为在滚道或滚动体上的光滑的底部凹痕, 通常与滚动体的间距相等,因冲击、不正确的安装/分解或轴承的掉落或有杂质被安装在里面了造成。 |

|

Brinelling (False) 摩擦腐蚀 |

False brinelling is characterized by surface marks or blemishes on raceways or rolling elements usually corresponding to rolling element spacing. The marks or blemishes will normally have a polished or satin finish. It’s usually caused by vibration in a non rotating bearing. 摩擦腐蚀的特征为在滚道或滚动体上的表面标记或瑕疵,通常与滚动体的间距相对应,标记或瑕疵通常有擦亮的或被磨光印痕,通常因在不旋转的轴承的振动造成。 |

|

Burnishing 磨光 |

Burnishing is a mechanical smoothing of a surface, sometimes resulting in discoloration around the contact area. This is a superficial characteristic that does not have wear. 磨光是一种表面的机械滑动,有时会导致接触区域周围的变色,这是一种没有磨损的表面特征。 |

|

Burrs/Raised Metal 毛刺/凸起金属 |

Burrs/Raised metal is positive displaced metal from original machining or from surface material being displaced because of scratches, scoring, dents etc. 毛刺/凸起的金属是原始加工或因划痕、刻痕、凹痕等导致表面材料发生位移而产生的正向位移金属。 |

|

Corrosion 腐蚀 |

Corrosion is a chemical reaction to the surface of the bearing as a result of moisture or other chemical exposure. It is characterized by a broken, pitted or discolored appearance. The surface might also have an “orange peel” appearance. (Refer to Figure 306) 腐蚀是由于潮湿或其他化学接触而导致轴承表面的化学反应。它的特征是破裂的、麻点或变色的外观。表面也可能有“桔皮”的外观。(参见图306) |

|

Cracks 裂纹 |

Cracks are separations, fissures, or ruptures characterized by sharp edges and/or sharp changes in direction. The sharp edges can be either jagged or straight but will not have a defined depth or bottom visually. 裂缝是由尖锐的边缘和/或方向的急剧变化所造成的分离、裂缝或破裂。锐利的边缘可以是锯齿状的,也可以是直的,但视觉上没有定义的深度或底部。 |

|

Dents 凹坑 |

Dents are slight depressions or hollows on the surface made by mechanical deformation of the surface by a blow or pressure caused by an object contacting the surface. They are usually bright bottomed and can be irregular in shape. Raised metal usually accompanies dents. (Refer to Figure 303) 有轻微的凹陷或凹陷的表面上的表面的机械变形的打击或压力由一个物体接触 表面造成了。它们通常是明亮的底部,形状可能不规则。凸起的金属通常伴随 凹痕。(参见图303) |

|

Discoloration (Chemical) 化学变色 |

Discoloration is a chemical reaction between two elements. Typically this is seen on cages that have been exposed to hot oil in operation. Sulfides in the oil turn the silver plate on the cages a purple to black color. 变色是两种元素之间的化学反应。典型的情况保持架在操作过程暴露在热油后 可以看到。油中的硫化物将保持架的银变成紫色和黑色。 |

|

Discoloration (Heat) 热变色 |

Heat discoloration of bearing surfaces are due to buildup of heat during engine operation or soak back after engine shutdown. The colors can range from straw, brown, purple, red purple and blue. (Refer to Figure 310, 312 and 313) 轴承表面的热变色是由于发动机运转过程中的热量积聚或发动机关闭后的回热。颜色可以是稻草、棕色、紫色、红色、紫色和蓝色。(见图310,312、图313) |

|

Flaking, Peeling and Blistering of Plating 镀层剥落、剥落和 起泡 |

Flaking, peeling and blistering of plating is delaminating of the plating from the parent material. This is caused by improper plating processes such as improper cleaning of the parent metal or plating parameters. (Refer to Figure 315) 剥落,剥落,从母材起泡脱层的镀层。这是由于电镀工艺不当造成的, 如不正 确地清洗母材或电镀参数。(参见图315) |

|

Fractures 断裂 |

Refer to Cracks. 参考裂缝。 |

|

Fretting/Fretting Corrosion 微动腐蚀 |

Fretting/Fretting Corrosion is rapid oxidation of surfaces in close fitting parts. It is characterized by rusty appearing surfaces ranging from black (well bonded) to fairly bright reddish brown (loosely bonded or free particles). It does not occur in the rolling element area. 微动腐蚀是零件表面的快速氧化。它的特征是表面生锈,从黑色(紧密结合) 到相当明亮的红棕色(松散结合或游离颗粒)。它不发生在滚动元素区域。 |

|

Frosting Rolling Elements/Race 滚动体、滚道磨砂 |

Frosting is the early stages of wear or superficial pitting or scoring. Generally cannot be measured unless it has progressed to pitting or scoring. It appears as a whitish or polished band which is made up of many minute indentations. 磨砂是磨损或表面凹陷或得分的早期阶段。 一般不能测量,除非它发展到点蚀 或划伤。它显示出白色或是由许多微小的缺口组成的抛光带。 |

|

Functional Surface 功能表面 |

Defined as the following: 定义如下: • Total raceway width of straight-through (non-flanged) races of roller bearings. 滚动轴承的直线(非法兰面)总滚道宽度 • Load paths on flanged raceways of roller bearings. 在滚动轴承上法兰滚道的负荷路径 • Roller OD load path. 滚子外径负荷路径 • Roller corner radius to end face intersection. 滚子拐角半径到相交表面末端。 • Roller bearing raceway guide flange inner surface. 滚子轴承滚道导向法兰内表面 • Separator pilot land surface 分离器或保持架接触表面 • Balls and ball bearing outer raceway. 滚珠和滚珠轴承外圈滚道。 • Ball bearing loaded raceway half for split inner rings. •加载路径对法兰滚道滚动轴承。 |

|

Galling 擦伤 |

Galling is a condition where there is a significant transfer of metal between surfaces due to welding and break-away of particles. It is caused by excessive sliding between two poorly lubricated surfaces which are forced into contact under high pressure. 擦伤是由于焊接和脱离颗粒造成的在表面发生金属位移的一种状态,它是由于两个润滑不良的表面在高压下被迫接触过度而造成。 |

|

Installation Marks 安装痕迹 |

Installation Marks are scratches, scuffs, galling or dents caused by mating part interface or tool interface during installation or removal. They are usually contained to ID, OD and face. 安装痕迹是在配合零件界面或在安装或分解中的工具界面产生的刮伤、摩擦、 或凹坑,通常存在于轴承的内径、外径和表面。 |

|

Nicks 刻痕 |

Refer to Dents. 参考凹坑 |

|

Non-Functional Surface 非功能表面 |

Defined as any surface that is not functional (Refer to definition of “functional”). 定义为任何不起作用的表面(参见“功能”的定义)。 |

|

Pits 麻点 |

Pits are small, irregular shaped cavities in a surface from which material has been removed by corrosive action such as chemical or electrolytic attack.(Refer to Figure 303) 麻点是一种表面小而不规则的空腔, 空腔是由化学或电解侵蚀等腐蚀作造成的 材料从表面去除(参见图303) |

|

Raised Metal 金属凸起 |

Refer to Burrs. 参考毛刺 |

|

Rust 生锈 |

Rust is the released particles due to corrosion leaving a reddish or reddish brown deposit on the surface. Refer to corrosion for details. 锈是由于腐蚀而释放出的微粒,在表面留下红棕色或红棕色的沉淀物。详情请 参阅腐蚀。 |

|

Scoring 擦伤 |

Scoring is a deep single or multiple scratches caused by sliding at the rolling contact surface as the result of foreign particle presence on the ball, roller or raceway. 擦伤是由于滚珠、滚道或滚道上的杂质颗粒在滚动接触表面滑动导致的一个或 多个划痕。 |

|

Scratches and Scuffs 刮痕 |

Scratches are narrow, shallow liner abrasions caused by the movement of sharp objects across a surface. Scuffs are multiple scratches aligned in the same direction as a unit. 划痕是窄而浅的衬线磨损,是由尖锐物体在表面移动引起的。Scuffs为多个划痕 排列在同一方向作为一个单位。 |

|

Silver-plate Flaking 银镀层脱落 |

Flaking is separation of silver-plating from the parent material. It is characterized by irregular shaped/sized pieces of silver coming loose. This is generally caused by contaminates during the plating process causing poor adhesion between the silver and parent material. 剥落是指镀银层从母体材料中分离出来。 其特征是不规则形状/大小的银片脱落。 这通常是由于电镀过程中的污染物导致银与母材之间的附着力较差造成的。 |

|

Silver-plate Pocket Wear 镀银凹槽磨损 |

Pocket wear is in the contact of the ball or roller with the working area of the cage causing an indentation or wear of the silver-plating. It is sometimes called silver flow because of silvers soft nature allowing it to appear moved around. The purpose of silver-plating is for lubrication between the rolling element and the cage during conditions of marginal oil lubrication. 凹槽磨损是指滚珠或滚子与保持架工作区域的接触造成镀银层的压痕或磨损。 由于银的柔软特性使其可以随意移动,因此有时也被称为银流。 镀银的目的是在边际油润滑条件下,在滚动体和保持架之间进行润滑。 |

|

Silver-plate Discoloration 银镀层变色 |

Discoloration of the silver plate to a dark color occurs generally from a chemical reaction to cleaning agents or some lubrication oils. 镀银层的变色通常是清洗剂或润滑油的化学反应造成的变色。 |

|

Skidding 打滑 |

Skidding is excessive slipping between balls/rollers and raceways. Skidding is evidenced by a frosted, speckled or burnished ring around the rolling elements or raceways. (Refer to Figure 313) 打滑是在球或滚珠与滚道之间过渡的滑动, 打滑显现出的形态为在滚动体或滚 道周围存在的磨砂、斑点或磨亮的环。(参见图 313) |

|

Spalling 散裂 |

Spalling is caused by fatigue. Spalling exhibits irregular shaped cavities of flaked out metal from a raceway or rolling element surface with jagged bottoms. (Refer to Figure 307 and 311) 散裂是由疲劳造成的。散裂呈现不规则的孔洞形态,从滚道或滚动体表面剥落金属,有粗糙的底部。(参见图 307 和 311) |

|

Stains 色斑 |

Stains are harmless surface discolorations which range from black to dark reddish brown in color. Surfaces which have stains will have an intact non-pitted and unbroken appearance. No change in dimensions will occur. 色斑是一种无害的表面变色,颜色由黑色到红棕,表面有色斑是没有麻点和没 有间断的显现,不会发生尺寸变化。 |

|

Surface Slag Inclusions 表面熔渣夹杂 |

Surfaces Slag Inclusions are foreign materials, embedded in the metal or a cold fold during the pouring of the metal. These are from manufacturer of the bearing material and can appear after bearing use. Generally irregular in shape with sharp features and may appear as dark spots or lines. 表面熔渣夹杂是外来材料,嵌入在金属或金属浇注过程中的冷褶皱。这些来自 轴承材料制造商,轴承使用后会出现。通常形状不规则,特征鲜明,可能出现 暗点或线条。 |

|

Varnishing 釉色 |

Varnishing is a harmless surface discoloration from the breakdown of a lubricant because of temperature, which results in a light brown to black appearance. No change in dimensions will occur. 釉色是一种因为润滑油高温分解后形成的表面变色,会导致显现一种浅棕到黑的颜色。不会发生尺寸改变。 |

|

Wear 磨损 |

Physical diminishing of the surface finish color and/or original machined surfaced. It does not constitute wear until detectable with an applicable stylus. In the early stages it may show up as a polished or bright track between the rolling elements and the race and cannot be measured. Advanced stages of wear may show up as looseness in the bearing, spalling, pitting, fretting or other surface defects. (Refer to Figure 307 and 312). 表面光洁度颜色和/或原始加工表面的物理减弱, 直到用合适的划针探检测出来前不视为磨损,在早期状态,在滚动体和滚道之间显示擦亮的光泽或明显的 印痕,但不能检测出来,进一步的磨损阶段以轴承的松动、散裂、点蚀、 微振磨损或其它的表面缺陷(参见图 307 和 312)。 |

(a) Ensure adequate inspection facility:

确保足够的检查设施:

1 Enclosed room with positive pressure.

正压封闭房间。

2 Temperature controlled 65 to 75°F (18 to 24°C).

温度控制在65到75 。F(18到24 。C)。

3 Relative humidity under 45 percent.

45%以下的相对湿度。

4 Lighting of 100 to 150 foot candles (1076 to 1615 lux).

100至150英尺的蜡烛的亮度(1076至1615力士)。

(b) Cleaning and visual check of installed or partially exposed bearings (installed in housings or on shafts/gears/etc) is permitted.

允许安装或部分暴露的轴承(安装在外壳或轴/齿轮等) 上进行清洁和目视检查。

(c) Prior to cleaning, demagnetize bearing so residual magnetism does not exceed five gauss.

清洁前, 磁轴承剩磁不超过五高斯。

(d) Prior to inspection, disassemble and clean bearing components per Method No. 203P.

在检查之前,根据方法203P拆卸并清洗轴承。

NOTE: Inspect the bearing functional surfaces per Table 302 using a precision stylus (Refer to Table 301 for definition of “functional”). When a stylus is used it shall have a tip radius as specified in Table 302. The stylus shall be held perpendicular to the surface being examined, and the only pressure exerted should be the weight of the stylus. Surface blemishes of acceptable bearings must not exceed the requirements specified in Table 302.

注:使用精密的笔针检查表302的轴承功能表面(参见表301“功能”的定义)。使用测针时,其针尖半径应符合表 302 的规定。测针应与被检查的表面垂直,施加的唯一压力应该是测针的重量。可接受轴承表面瑕疵不得超过表302规定的要求。

Reassembled bearings must contain only original components and be oriented the same as originally installed, except as noted below:

重新组装的轴承必须只包含原始组件和面向最初安装相同,除了以下说明:

Half complement roller bearings (unused pockets between each roller) that are worn beyond limits may have the rollers reassembled into unused pockets.

磨损超过极限的半满装滚子轴承(每个滚子之间有未使用的凹槽)可将滚子重新装配到未使用的凹槽中。

Bearings with cages worn beyond limits on one (1) side of the pocket may have the cage turned 180 degrees to position the unused side of the pocket for use. There is no requirement to re-mark the cage markings on the other side.

当带保持架的轴承一侧磨损超过极限时,可将保持架翻转 180 度,使轴承保持架未使用的一侧投入使用。 无需在另一侧重新标记保持架标记。

(h) Dip bearing in oil (MIL-L-6085, SECTION VII) heated to 120 to 140°F (49 to 60°C) for five minutes and allow to drain. Do not oil bearings used in pneumatic valves.

将轴承浸入加热至 49 至 60°C (120 至 140°F) 的油 (MIL-L-6085,第 VII 章)中五分钟,然后沥干。 不要给气动阀中使用的轴承加油。

(i) Package bearing and part number identification in heat sealable transparent plastic bag (MIL-B-22191D, SECTION VII). Evacuate air from bag and heat seal shut.

用热封透明塑料袋包装轴承和件号标识(MIL-B-22191D,第 VII 章)。 排出袋中空气并热封。

|

ROLLING ELEMENT DIAMETER SIZE TO DETERMINE DEFECT SIZE PERMITTED 滚动体直径尺寸,以确定允许的缺陷尺寸 |

.500 inch (12.7 mm) or less |

Over .500 inch (12.7 mm) to 1.00 inch (25.4 mm) |

Over 1.00 (25.4 mm) |

||

|

STYLUS TIP RADIUS USED TO DETECT DEFECT 用于检测缺陷的测尖半径 |

0.04inch (1.016 mm) |

0.08inch (2.032 mm) |

0.12inch (3.048 mm) |

||

|

CONDITION/DEFECT 状态/缺陷 |

FUNCTIONAL SURFACE REQUIREMENTS 工作表面的要求 |

FUNCTIONAL SURFACE DEFECT SIZ 工作表面缺陷的尺寸 |

NONFUNCTIONAL SURFACE 非工作表面 |

||

|

Arcing 打火 |

Not permitted 不允许 |

NA 不适用 |

NA 不适用 |

NA 不适用 |

Not Permitted 不允许 |

|

Bent 弯曲 |

Not permitted 不允许 |

NA 不适用 |

NA 不适用 |

NA 不适用 |

Not Permitted 不允许 |

|

Brinelling (True) 冲击腐蚀 |

Permitted. No raised metal permitted. Stone to remove raised metal. 被允许.不允许凸起 金属。用磨石去除凸 起的金属。 |

.020 inch (0.508 mm) |

.030 inch (0.762 mm) |

.040 inch (1.016 mm) |

Not Applicable 不适用 |

|

Brinelling (False) 摩擦腐蚀 |

Permitted.No raised :metal permitted. Stone to remove raised metal. 被允许.不允许凸起 金属。用磨石去除凸 起的金属。 |

.020 inch (0.508 mm) |

.030 inch (0.762 mm) |

.040 inch (1.016 mm) |

Not Applicable 不适用 |

|

Burnishing 被磨亮 |

Permitted if step is not detectable with applicable stylus. 如果使用适用的测针无法检测到台阶,则允许使用 |

NA |

NA |

NA |

Not Applicable 不适用 |

|

Burrs 毛刺 |

Not permitted. Use stone to remove burr. Refer to appropriate defect this table causing burr. 不允许。用磨石去除 毛刺。参考本表的适 当缺陷引起毛刺。 |

NA |

NA |

NA |

Not permitted.Use stone to remove burr. Refer to appropriate defect this table causing burr 不允许。用磨石去除毛刺。参 考本表的适当缺陷引起毛刺。 |

|

Corrosion 腐蚀 |

Not permitted.Remove corrosion. Refer to appropriate defect this table. 不允许。清除腐蚀。参考相应的缺陷表。 |

NA |

NA |

NA |

Not permitted.Remove corrosion. Refer to appropriate defect this table. 不允许。清除腐蚀。参考相应的缺陷表。 |

|

Cracks (All Components) 裂纹(针对所有零 件) |

Not permitted. (Visual check). 不允许(目视检查) |

NA |

NA |

NA |

Not permitted. (Visual check). 不允许(目视检查) |

|

Deformation Separator Silver-plate or Bronze 镀银或铜保持架的 变形 |

Not permitted. 不允许 |

NA |

NA |

NA |

Not Applicable 不适用 |

|

Dents 凹坑 |

Permitted. No raised metal permitted. Stone to remove raised metal. 允许。 没有金属凸 起是允许的。用磨石 去除凸起的金属 |

.020 inch (0.508 mm) |

.030 inch (0.762 mm) |

.040 inch (1.016 mm) |

Permitted. No raised metal permitted.Stone to remove raised metal. 0.125 inch (3.175 mm) defect permitted. 允许。 没有金属凸起 是允许的。用磨石去 除凸起的金属。允许有 0.125 英寸(3.175 毫米)的缺陷。 |

|

Discoloration (Chemical) 变色(化学) |

Permitted. 允许 |

NA |

NA |

NA |

Permitted. 允许 |

|

Discoloration (Heat) 变色(热变色) |

Straw or brown color permitted.Red-purple, purple, blue are permitted if RC 58 minimum is met when checked three (3) places each on inner & outer race faces. Stone to remove raised metal from hardness test. 淡黄色或棕色是允 许的,红-紫,紫色、 蓝色如果内环和外环的三个点的硬度大于RC58是允许的,在硬度测试后用磨石去掉金属凸起 |

NA |

NA |

NA |

Straw or brown color permitted.Red-purple, purple,blue are permitted if RC 58 minimum is met when checked three (3) places each on inner & outer race faces. Stone to remove raised metal from hardness test. 淡黄色或棕色是允许 的,红-紫,紫色、蓝 色如果内环和外环的 三个点的硬度大于RC58是允许的,在硬 度测试后用磨石去掉金属凸起 |

|

Discoloration (Separator) Silver-plate and Bronze 镀银和铜保持器的 变色 |

Permitted. Must meet all other criteria. 允许,必须满足所有其它的标准 |

NA |

NA |

NA |

Permitted. 允许 |

|

Flaking Separator Silver-plate 镀银保持架剥落 |

Not permitted. 不允许 |

NA |

NA |

NA |

Not permitted. 不允许 |

|

Fractures 破碎 |

Not permitted. (Visual check). 不允许(目视检查) |

NA |

NA |

NA |

Not permitted. (Visual check). 不允许(目视检查) |

|

Fretting/Fretting Corrosion 微振磨损/锈蚀 |

NA |

NA |

NA |

NA |

Permitted if less than 30% of surface is affected. 如果受影响面积少于 30%,则允许使用。 |

|

Frosting Rolling Elements/Races 滚动元件、滚道磨 砂 |

Permitted if not detectable with applicable stylus. 如果用测针检查不 出来是允许的 |

NA |

NA |

NA |

NA |

|

Galling 磨损 |

Not permitted. No transfer of metal is permitted. 不允许。不允许金属 转移。 |

NA |

NA |

NA |

Permitted. No raised metal permitted.Stone to remove raised metal. 允许.不允许凸起金属。用磨石去除凸起的金属。 |

|

Installation Marks OD,ID & Faces 外径、内径和端面安装伤痕 |

Permitted. Refer to appropriate defect this table. 被允许.参考相应的 缺陷表。 |

NA |

NA |

NA |

Permitted. No raised metal permitted. Use stone to remove raised metal. Defect size of 0.125 inch (3.175 mm) depth maximum permitted. 被允许.不允许凸起金 属。 用磨石去除凸起的金属。允许最大缺陷深度为 0.125 英寸(3.175 毫米)。 |

|

Nicks 刻痕 |

Permitted. No raised metal permitted. Use stone to remove raised metal. 被允许.不允许凸起 金属。用磨石除去凸 起的金属。 |

.020 inch (0.508 mm) |

.030 inch (0.762 mm) |

.040 inch (1.016 mm) |

Permitted. No raised metal permitted. Use stone to remove raised metal. Defect size of 0.125 inch (3.175 mm) depth maximum permitted. 被允许.不允许凸起金 属。用磨石除去凸起 的金属。缺陷尺寸为 0.125英寸(3.175毫 米)的最大允许深度。 |

|

Pits Races & Rolling Elements 麻点 滚道或滚动体 |

Permitted. No more than 3 defects within a .250 inch (6.35 mm)diameter circle. 允许, 在6.35mm 直径范围内部超过3 处缺陷 |

.010 inch (0.508 mm) |

0.14 inch (0.762 mm) |

.018 inch (1.016 mm) |

Permitted if no more than 5 defects of 0.060 inch (1.523 mm) size on one surface. Not permitted in radii or chamfers. 如果在一个表面上不 超过5处大小为 1.523mm的缺陷。 在 经向或倒角处不允许有。 |

|

Pits Separators Silver-plate or Bronze 在镀银或镀铜的保 持架上的麻点 |

Permitted. .020 inch (0.508 mm) maximum size. 允许,大小不超过 0.508mm . |

NA |

NA |

NA |

NA |

|

Rust 锈蚀 |

Not permitted. Remove rust. Refer to appropriate defect this table. 不允许, 去除锈蚀。 |

NA |

NA |

NA |

Remove rust. Refer to appropriate defect this table. 除锈。参考相应的缺陷表。 |

|

Scoring 擦痕 |

Permitted. Single defect in 0.5inch Dia. circle. No raised metal permitted, stone to remove. 允许。 0.5 英寸直径圆内的单个缺陷。 不允许有凸起的金属,可以磨石移除。 |

Max. length equal to rolling element Dia. 最大长度= 滚动体的 直径 |

Max. length equal to rolling element Dia. 最大长度= 滚动体的 直径 |

Max. length equal to rolling element Dia. 最大长度= 滚动体的 直径 |

Not Applicable 不适用 |

|

Multiple defects in 0.5inch Dia circle. No raised metal permitted, stone to remove. 0.5 英寸直径圆圈内有多个缺陷。 不允许有凸起的金属,磨石可以去除。 |

Three maximum ,individual defect length half or less of rolling element Dia. 三最大,个 别缺陷长 度的一半 或更少的 滚动元素 直径。 |

Three maximum , individual defect length half or less of rolling element Dia. 三最大,个 别缺陷长 度的一半 或更少的 滚动元素 直径。 |

Three maximum ,individual defect length half or less of rolling element Dia. 三最大,个 别缺陷长 度的一半 或更少的 滚动元素 直径。 |

Not Applicable 不适用 |

|

|

Circumferential defects. No raised metal permitted, stone to remove. 周向缺陷。不允许金 属凸起,可以用磨石 移除。 |

Three defects maximum , length of rolling elements circumfer ence or less. 三缺陷最 大,滚动元 件周长或 小于。 |

Three defects maximum , length of rolling elements circumfer ence or less. 三缺陷最 大,滚动元 件周长或 小于。 |

Three defects maximum , length of rolling elements circumfer ence or less. 三缺陷最 大,滚动元 件周长或 小于。 |

Not Applicable |

|

|

Crossed scoring 交叉得分 |

Not permitted 不允许 |

Not permitted 不允许 |

Not permitted 不允许 |

Not permitted 不允许 |

|

|

Scratches and Scuffs Balls/Rollers Inner/Outer Races 划痕和擦伤 滚珠/滚轮 内圈/外圈 |

Permitted. 允许 |

Not Applicable 不适用 |

|||

|

Single defect in 0.500 (12.7 mm) Dia. circle. No raised metalpermitted, stone to remove. 0.500 (12.7 mm) 直径圆内的单个缺陷。 不允许有凸起的金属,可以 用磨石移除。 |

Max.length equal to rolling Element Dia. 最大长度等于滚动体直径。 |

Max.length equal to rolling Element Dia. 最大长度等于滚动体直径。 |

Max.length equal to rolling Element Dia. 最大长度等于滚动体直径。 |

Not Applicable 不适用 |

|

|

Multiple defects in 0.500 (12.7 mm) Dia. circle. No raised metal permitted, stone to remove. 在 0.500(12.7 毫米)直径圆内有多个缺陷。 无凸起的金属允许,磨石可去除。 |

Three maximum individual defect Length half or less of rolling Element Dia. 三个最大单个缺陷 长度等于或小于滚动体直径的一半 |

Three maximum individual defect Length half or less of rolling element Dia. 三个最大单个缺陷 长度等于或小于滚动体直径的一半 |

Three maximum individual defect Length Half or less of rolling Element Dia. 三个最大单个缺陷 长度等于或小于滚动体直径的一半 |

Not Applicable 不适用 |

|

|

Scratches and Scuffs Balls/Rollers Inner/Outer Races (Cont) 划痕和擦伤 滚珠/滚轮 内圈/外圈(续) |

Circumferential defects. No raised metal permitted,stone to remove. 周缘缺损。 不允许有凸起的金属,磨石可以去除。 |

Three defects maximu m,length of rolling elements circumfe rence or less. 最大三个缺陷,滚动体周长或更短。 |

Three defects maximum,length of rolling element scircumference or less. 最多三个缺陷,滚动体圆周长度或更短。 |

Three defects maximu m,length of rolling elements circumference or less. 最大三个缺陷,滚动体圆周长度或更短。 |

Not Applicable 不适用 |

|

Crossed scratches and scruffs. 交叉划痕和颈背。 |

NA |

NA |

NA |

Not Applicable 不适用 |

|

|

Skidding 打滑 |

Permitted. No raised metal permitted.Use stone to remove raised metal. 被允许.不允许凸起 金属。用磨石除去凸 起的金属。 |

.020 inch (0.508 mm) |

.030 inch (0.762 mm) |

.040 inch (1.016 mm) |

Not Applicable 不适用 |

|

Spalling 剥落 |

Not permitted. 不允许 |

NA |

NA |

||

|

Stains 色斑 |

Permitted surface discoloration only, if felt with applicable stylus bearing must be cleaned again. 仅允许表面褪色,如果用适用的测针轴承感觉到褪色,则必须再次清洁。 |

NA |

NA |

||

|

Surface Slag Inclusions 表面夹渣 |

No slag inclusions permitted on functional surfaces. 功能表面不允许夹渣 |

NA |

NA |

||

|

Varnishing 釉色 |

Permitted surface discoloration only, if felt with applicable stylus bearing must be cleaned again. 仅允许表面褪色,如果用适用的测针轴承感觉到褪色,则必须再次清洁。 |

NA |

NA |

NA |

Permitted surface discoloration only, if felt with applicable stylus bearing must be cleaned again. 仅允许表面褪色,如果用适用的测针轴承感觉到褪色,则必须再次清洁。 |

|

Wear (Roller Bearing) 磨损(滚子轴承) |

Wear is permitted only on each end from center out, 50% of roller end area. 只允许从中心向外磨损两端,占滚子端部面积的 50%。。 |

Step not permitted between rolling element path and raceway. Corner Radius wear not permitted. 滚动体通道和滚道之间不允许有台阶。 不允许转角半径磨损。 |

Step not permitted between rolling element path and raceway. Corner Radius wear not permitted. 滚动体通道和滚道之间不允许有台阶。 不允许转角半径磨损。 |

Step not permitted between rolling element path and raceway. Corner Radius wear not permitted. 滚动体通道和滚道之间不允许有台阶。 不允许转角半径磨损。 |

Permitted if within Tolerance (average) of ID, OD or face. 如果在内径、外径或端面公差(平均值)范围内,则允许。 |

|

Wear, Pocket Silverplate(Separator) 保持架镀银层(分 离器)磨损 |

Permitted wear at contact between rolling element and cage cannot be more than .080 inch (2.032 mm) maximum in size, any shape. 滚动体与保持架接触处的允许磨损最大尺寸不能超过 0.080 英寸(2.032 毫米),形状不限。 |

NA |

NA |

NA |

NA |

|

Wear, Pocket Bronze (Separator) 保持架镀铜层(分 离器)磨损 |

Permitted wear at contact between rolling element and cage cannot be more than .080 inch (2.032 mm) maximum in size, any shape. 滚动体与保持架接触处的允许磨损最大尺寸不能超过 0.080 英寸(2.032 毫米),形状不限。 |

NA |

NA |

NA |

NA |

|

Wear, Separator OD/ID Guide Silver-plate 分离器/镀银导向盘内 外径磨损 |

Permitted. No wear through to parent 允许。 不得穿透基材 |

NA |

NA |

NA |

NA |

![图片[1]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-1.png)

![图片[2]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-2.png)

NOTE: Typical ball defects not permitted (refer to Table 302):

注:不允许存在典型的球形缺陷(参考 表302):

1 Circumferential bands.

环形带。

a .Continuous heavy thrust loading without ball changing axis of rotation, crushing of the microscopic high spots. Refer to Figure 302.

在球不改变旋转轴的情况下持续承受重推力负荷,粉碎微观高点。 参见图 302。

2 Cracked.

裂纹.

NOTE: Cracks are due to forming laps that were missed in manufacturing operation.

注:裂纹是由于制造过程中没有包裹形成的。

a .Dark line. A scratch is easily mistaken for a crack.

暗线。划痕很容易被误认为是裂纹。

3 Hard particle indents.

硬质粒子压痕。

NOTE: Often called spalling.

注:通常称为剥落。

a .Surface indications that were caused by hard contaminants.

表面污染物是由硬污染物引起的。

4 Rust.

锈。

a .Brown stains and hemispherical pits.

棕色污渍和半球形凹坑。

5 Fatigue spalling.

疲劳剥落。

a .Irregular sharp edged holes. Metal has broken out.

不规则锐边孔。金属已脱落。

6 Dented.

凹陷。

a .Crescent shaped depression. Shallow and rounded. Assembly/disassembly damage. Cut by inner or outer raceway edge. Refer to Figure 303.

新月形凹陷。浅圆。装配/拆卸损伤。由内侧或外侧滚道边缘切割。参见图303。

7 Inclusion.

包含.

a .Void with flush edges, slag or forging flaw.

带有冲边、熔渣或锻造缺陷的空洞。

8 Matted surface.

哑光表面。

a .A multitude of criss crossing scratches. Caused by abrasive contaminants lodged in separator ball pockets.

大量纵横交错的划痕。由分离器球袋中的磨料污染物引起的。

9 Pitted.

坑

a .Refer to Figure 304.

参见图304

![图片[3]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-3.png)

![图片[4]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-4.png)

![图片[5]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-5.png)

NOTE: Typical roller defects not permitted (refer to Figure 305 and Table 302):

注:不允许存在典型的滚柱缺陷(参见图305和表302):

1 Wide or heavy wear.

严重磨损

a. Misaligned – inner to outer rings.

内环与外环的错位

b. Guide flange deformed by clamping.

导向法兰变形

2 Eccentric buff.

偏心磨亮

a. Roller end radius is not concentric or roller is slightly off square.

滚柱末端半径不同轴或滚柱有轻微的尺寸偏斜。

3 Wide buff.

大范围暗色

a. Typical wear condition on high time rollers that have had a normal operating life.

在高寿滚柱典型的磨损状态。已经超过了正常工作时间。

4 Fatigue pitting/frosting.

在暗色之后的状态。在高寿滚柱上普遍曾在。

a. This condition is in the after buff stage. Common to high time rollers.

疲劳剥蚀/无光泽面

5 Spalling.

散裂

a . Heavy distress on roller end usually a wide band.

滚准上的严重的金属疲劳,通常是大范围的。

6 Eccentric wear.

偏心磨损

a . Same as Step 1, except that the roller is off square as well.

除第一步外,又出现尺寸偏斜

7 Roller end rings.

轴承挡圈对滚柱的磨损

a . Hard particles lodged in roller separator pocket.

硬的颗粒停留在轴承保持架上导致的磨损。

8 Cracked.

裂纹

NOTE: Cracks on rollers are always a manufacturer’s defect.

注:滚柱的裂纹通常是制造商制造缺陷

a. Forging lap that became evident in service.

锻造的折皱造成使用时出现的明显的缺陷

9 Spiral groove (causes).

旋转槽

a. Roller dislodged during assembly.

滚柱在安装时脱落造成。

b. Outer race was forced on by screwing its lead in corner over the roller. Thus, leaving a groove.

组装滚柱时外圈受力, 离开沟槽

10 Smeared and raised metal.

污迹或金属凸起

a. Forceful assembly.

强制性装配

11 Indent lines.

锯齿状线

a. Hung rollers similar to spiral groove.

把滚柱敲进沟槽

12 Rings, scratches.

环形刮伤

a. Same as Step 7.

与第7步一样。

![图片[6]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-6.png)

![图片[7]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-7.png)

![图片[8]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-8.png)

NOTE: Outer raceways defects not permitted (refer also to Figure 308 and Table 302).

注:外滚道不允许有缺陷

1 Starburst.

星爆

a. Hard brittle particle damage deformed surface appearance.

硬颗粒造成的表面损伤

2 Ball corner flat.

球角平

a. Ball with crescent shaped indent.

球面有月牙型的切割

3 Active surface cracks.

有效表面的裂纹

a. Spalling will follow typical on tube stolic outer race.

在外圈上典型的破裂

4 Brinells mounting.

Brinells安装。

a. Static loading the balls into the raceway.

球作用在滚道上的静载荷造成的损伤

5 Roller skidding.

滚道的拉伤

a. The surface lay will be smeared.

表面层污迹

6 Roller corner flat.

滚子角平平面

a. Damage on roller is present.

滚道上的损坏

7 False brinelling.

腐蚀

a. Brown iron oxide residue and equidistant fret lines.

深褐色的氧化铁残渣和等距的侵蚀痕迹

![图片[9]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-9.png)

![图片[10]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-10.png)

![图片[11]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-11.png)

![图片[12]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-12.png)

![图片[13]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-13.png)

![图片[14]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-14.png)

NOTE: Separator defects not permitted (refer to Figure 314 and Table 302).

注:保持架不允许有缺陷

1 Silver flow, heavy.

银镀层重度积压流动

a. Typical on high time and excessive silver plate.

在高寿的银镀层上的典型失效

2 Flaking.

剥落

a. Poor plating adhesion.

镀层附着力低

3 Hard particles.

硬的颗粒

a. Lodged in separator pocket.

停留在保持架上

4 Circle “B” indicates balance.

圆B指示平衡

5 Exposed base metal.

暴露的金属基体

6 Cracked.

裂纹

a. Extreme opposed loads. On ball type separator the cracking is due to misalignments.

极端重载。在球轴承上裂纹的缺陷是由于偏心造成(轴承安装时未对准)

7 Heavy wear.

严重磨损

a. Cage is out of balance.

保持架已不平衡

![图片[15]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-15.png)

![图片[16]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-16.png)

![图片[17]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-17.png)

(2) Non-Separable Bearings:

不能分离的轴承

|

Terms 项目 |

Definition (Description of Defect) 定义(缺陷的描述) |

|

Arcing 弧光 |

Round pit shaped cavity in a surface from which metal has been removed by electrical arc causing a temper change (softer) in the metal around the pit shaped cavity. It may be caused by a lightning strike or similar electrical occurrence. This typically appears as excessive noise on the analyzer. 在金属表面被电弧除去的圆形坑状空腔,使坑状空腔周围的金属发生回火变 化(软)。可能是快速冲击或类似的电气事故引起的。这通常显示为分析仪 上的过度噪声。 |

|

Bent 弯曲 |

Deformed from original shape or form . An example would be cages that are deformed from improper installation or bearing wear. This typically appears as excessive noise on the analyzer. 从原来的形状或形式变形。例如安装不当或轴承磨损变形的保持架。这通常 显示为分析仪上的过度噪声。 |

|

Brinelling (True) 冲击腐蚀 |

True brinelling is plastic flow of metal, characterized by smooth shiny bottomed indentations in raceways or rolling elements usually equally spaced corresponding to rolling element spacing. Caused by impact, improper installation or dropping of the bearing or unit it is installed in. This typically appears as excessive noise on the analyzer. (Refer to Figure 309). 冲击腐蚀是金属塑性流动, 以光滑闪亮的平底凹槽滚道或滚动元件通常等距 对应滚动元件的间距。由于撞击、安装不当或轴承安装不当造成的。这通常 显示为分析仪上的过度噪声。(参见图309)。 |

|

Brinelling (False) 摩擦腐蚀 |

False brinelling is characterized by surface marks or blemishes on raceways or rolling elements usually corresponding to rolling element spacing. The marks or blemishes will normally have a polished or satin finish. It is usually caused by vibration in a non rotating bearing. False brinelling will not typically appear as excessive noise on the analyzer. 摩擦腐蚀的特点是表面瑕疵或滚动元件滚道滚动间距通常对应。标记或瑕疵 通常会有抛光或缎面处理。它通常是由非旋转轴承振动引起的。 摩擦腐蚀通 常不会引起在分析仪过大的噪声。 |

|

Burnishing 磨光 |

Burnishing is a mechanical smoothing of a surface, sometimes resulting in discoloration around the contact area. This is a superficial characteristic that does not have wear. 磨光是表面的机械滑动,有时导致在接触面积变色。这是表面上没有磨损的 特性。 |

|

Burrs/Raised Metal 毛刺或金属凸起 |

Burrs/Raised metal is positive displaced metal from original machining or from surface material being displaced because of scratches, scoring, dents etc. This typically appears as excessive noise on the analyzer. 毛刺/凸起的金属是由原来的机械加工而产生的正位移金属或由于划痕、刻 痕、凹痕等而被移位的表面材料。 |

|

Corrosion 腐蚀 |

Corrosion is a chemical reaction to the surface of the bearing as a result of moisture or other chemical exposure. It is characterized by a broken pitted or discolored appearance. The surface might also have an “orange peel” appearance. (Refer to Figure 306). 腐蚀是由于潮湿或其他化学接触而导致轴承表面的化学反应。它的特点是间 断的麻点或变色的外观。表面也可能有“桔皮”的外观。(参见图306)。 |

|

Cracks 裂纹 |

Cracks are separations, fissures, or ruptures characterized by sharp edges and/or sharp changes in direction. The sharp edges can be either jagged or straight but will not have a defined depth or bottom visually. 裂缝是由尖锐的边缘和/或方向的急剧变化所造成的分离、裂缝或破裂。锐利的边缘可以是锯齿状的,也可以是直的,但视觉上没有固定的深度或底部。 |

|

Dents 弯曲 |

Dents are slight depressions or hollows on the surface made by mechanical deformation of the surface by a blow or pressure caused by an object contacting the surface. They are usually bright bottomed and can be irregular in shape. Raised metal usually accompanies dents. This typically appears as excessive noise on the analyzer. (Refer to Figure 303). 有轻微的凹陷或凹陷的表面上的表面的机械变形的打击或压力由一个物体接触表面造成了。它们通常是明亮的底部,形状可能不规则。凸起的金属通常伴随凹痕。这通常显示为分析仪上的过度噪声。(参见图303)。 |

|

Discoloration (Chemical) 色变(化学) |

Discoloration is a chemical reaction between two elements. Typically this is seen on cages that have been exposed to hot oil in operation. Sulfides in the oil turn the silver plate on the cages a purple to black color. 变色是两种元素之间的化学反应。典型的情况是在操作过程中暴露在热油中 的保持架上。油中的硫化物将保持架里的银镀层变成紫色和黑色。 |

|

Discoloration (Heat) 色变(热) |

Heat discoloration of bearing surfaces are due to buildup of heat during engine operation or soak back after engine shutdown. The colors can range from straw, brown, purple, red purple and blue. This typically appears as excessive noise on the analyzer. (Refer to Figures 310 and 312). 轴承表面的热变色是由于发动机运转过程中的热量积聚或发动机关闭后的回热。颜色可以是稻草、棕色、紫色、红色、紫色和蓝色。这通常显示为分 析仪上的过度噪声。(参考图310和图312)。 |

|

Flaking, Peeling and Blistering of Plating 剥落或镀层脱落 |

Flaking, peeling and blistering of plating is delaminating of the plating from the parent material. This is caused by improper plating processes such as improper cleaning of the parent metal or plating parameters. This typically appears as excessive noise on the analyzer. (Refer to Figure 315). 剥落,剥落,起泡从母材上镀层脱落。这是由于电镀工艺不当造成的, 如不 正确地清洗母材或电镀参数。这通常显示为分析仪上的过度噪声。(参见图 315)。 |

|

Fractures 破碎 |

Refer to Cracks. 参考裂纹 |

|

Fretting/Fretting Corrosion 微振腐蚀 |

Fretting/Fretting Corrosion is rapid oxidation of surfaces in close fitting parts. It is characterized by rusty appearing surfaces ranging from black (well bonded) to fairly bright reddish brown (loosely bonded or free particles). It does not occur in the rolling element area. 微振腐蚀是在封闭压配合零件表面的快速氧化。主要特征为表面出现黑色 (连续) 到红棕色的(松散或自由的颗粒) 锈蚀。 微振腐蚀不会发生在滚动体表面。 |

|

Frosting Rolling Elements/Races 滚子元件或滚道的没 有光泽 |

Frosting is the early stages of wear or superficial pitting or scoring. It appears as a whitish or polished band which is made up of many minute indentations. This typically appears as excessive noise on the analyzer. 结霜是磨损或表面凹陷或得分的早期阶段。它显现出一个白色的或由许多微 小的缺口形成的抛光带。这通常显示为分析仪上的过度噪声。 |

|

Functional Surface 功能表面 |

Defined as the following: 定义如下: •Total raceway width of straight-through (non-flanged) races of roller bearings. 滚动轴承的直线(非法兰面)总滚道宽度 •Load paths on flanged raceways of roller bearings. 在滚动轴承上法兰滚道的负荷路径 •Roller OD load path. 滚子外径负荷路径 •Roller corner radius to end face intersection. 滚子拐角半径到相交表面末端。 •Roller bearing raceway guide flange inner surface. 滚子轴承滚道导向法兰内表面 •Parator pilot land surface 分离器或保持架接触表面 •Balls and ball bearing outer raceway. •滚珠和滚珠轴承外圈滚道。 •Ball bearing loaded raceway half for split inner rings. •加载路径对法兰滚道滚动轴承。 |

|

Galling 擦伤 |

Galling is a severe condition where there is significant transfer of metal between surfaces due to welding and break-away of particles. It is caused by excessive sliding between two poorly lubricated surfaces which are forced into contact under high pressure. This typically appears as excessive noise on the analyzer. 磨损是一种由于焊接和脱离颗粒在表面发生的有明显的金属转移的状况。它是由于两个润滑不良的表面在高压下被迫接触过度而造成的。这通常显示为分析仪上的过度噪声。 |

|

Installation Marks 安装伤痕 |

Installation Marks are scratches, scuffs, galling or dents caused by mating part interface or tool interface during installation or removal.They are usually contained to ID, OD and face. 安装伤痕是因为配合部分接口或工具安装或拆卸过程中的界面的划痕, 磨 损,磨损或凹痕。它们通常包含在ID 、OD和表面。 |

|

Nicks 刻痕 |

Refer to Dents. 参考凹痕。 |

|

Non-Functional Surface 非工作表面 |

Defined as any surface that is not functional (Refer to definition of “functional”). 定义为任何不起作用的表面(参见“功能”的定义)。 |

|

Pits 麻点 |

Pits are small, irregular shaped cavities in a surface from which material has been removed by corrosive action such as chemical or electrolytic attack. 麻点是表面通过化学方法或点解方法去腐蚀后材料被去除而形成的小的、不 规则的凹坑。 |

|

Raised Metal 金属堆积 |

Refer to Burrs. 参考毛刺 |

|

Rust 锈蚀 |

Rust is the released particles due to corrosion leaving a reddish or reddish brown deposit on the surface. Refer to corrosion for details. 锈是由于腐蚀而释放出的微粒,在表面留下红棕色或红棕色的沉淀物。详情请参阅腐蚀。 |

|

Scoring 擦痕 |

Scoring is a deep single or multiple scratches caused by sliding at the rolling contact surface as the result of foreign particle presence on the ball, roller or raceway. 擦痕是由于滚珠、滚道或滚道上的杂质颗粒在滚动接触表面滑动导致的一个或多个划痕。 |

|

Scratches and Scuffs 刮伤和磨损 |

Scratches are narrow, shallow liner abrasions caused by the movement of sharp objects across a surface. Scuffs are multiple scratches aligned in the same direction as a unit. 划痕是窄而浅的衬线磨损,是由尖锐物体在表面移动引起的。 Scuffs为多个 划痕对齐在同一方向形成一个单位。 |

|

Silver-plate Flaking 镀银层剥落 |

Flaking is separation of silver-plating from the parent material. It is characterized by irregular shaped/sized pieces of silver coming loose. This is generally caused by contaminates during the plating process causing poor adhesion between the silver and parent material. (Refer to Figure 315). 剥落是银镀层与母材的分离。它的特点是不规则形状/大小的银片松动。这通常是造成污染的电镀工艺,使银和母材之间的粘合性较差造成的。(参见图315)。 |

|

Silver-plate Pocket Wear 镀银层磨损 |

Pocket wear is the contact of the ball or roller with the working area of the separator causing an indentation or wear of the silver plating. The purpose of silver plating is to provide lubricant between rolling element and separator if oil lubrication is marginal. 保持架磨损是球或滚子与分离器工作区域的接触, 造成镀银的压痕或磨损。镀银的目的是在润滑油边缘润滑的情况下,在轧制元件和分离器之间提供润滑剂。 |

|

Silver-plate Discoloration 镀银层变色 |

Discoloration of the silver plate to a dark color occurs generally from a chemical reaction to cleaning agents or some lubrication oils. 银镀层的变色通常是从清洗剂或润滑油之间的化学反应产生的变色。 |

|

Skidding 打滑 |

Skidding is excessive slipping between balls/rollers and raceways.Skidding is evidenced on non-separable bearings typically appears as looseness and excessive noise on the analyzer. (Refer to Figure 313). 打滑过度滑球或滚子和滚道之间。在不可分离的轴承上,打滑现象通常表现为分析仪上的松动和过大的噪音。(参见图313)。 |

|

Spalling 剥落 |

Spalling is caused by fatigue. Spalling on non-separable bearings typically appears as roughness and excessive noise on the analyzer. (Refer to Figure 311). 剥落是因为疲劳造成的。在不能分离的轴承上的剥落会在分析仪上出现刺耳 的、大的噪音。 |

|

Stains 色斑 |

Stains are harmless surface discolorations which range from black to dark reddish brown in color. Surfaces which have stains will have an intact non-pitted and unbroken appearance. No change in dimensions will occur. 色斑是一种无害的表面变色,颜色从黑色到深棕红色。表面有色斑的是一种完整的没有麻点,没有打断的显现。尺寸不会发生变化。 |

|

Surface Slag Inclusions 表面夹杂残渣 |

Surfaces Slag Inclusions are foreign materials, embedded in the metal or a cold fold during the pouring of the metal. These are from manufacture of the bearing material and can appear after bearing use. Generally irregular in shape with sharp features and may appear as dark spots or lines. 表面夹杂是一种外来物,在浇筑过程中夹杂在金属中。在制造过程中就有, 在轴承使用后出现。通常为不规则的形状, 可能显现黑点或线。 |

|

Varnishing 釉子 |

Varnishing is a harmless surface discoloration from the breakdown lubricant because of temperature, which results in a light brown to black appearance. No change in dimensions will occur. 釉子是一种因为润滑剂在高温下分解形成的一种无害的表面变色,会导致显现浅棕到黑的颜色,尺寸不会发生变化。 |

|

Wear 磨损 |

Physical diminishing of the surface finish and/or original machined surfaced. It does not constitute wear until detectable on the analyzer as excessive noise. 表面光洁度或原始加工尺寸减小,在分析仪上以噪声形式表现出的不构成磨 损。 |

(a) Ensure adequate inspection facility:

确保足够的检查设施

1 Enclosed room with positive pressure.

确保房间合适的压力。

2 Temperature controlled 65 to 75°F (18 to 24°C).

温度控制为8-24°C。

3 Relative humidity under 45 percent.

相对湿度小于45%。

4 Lighting of 100 to 150 foot candles (1076 to 1615 lux).

亮度为1076-1615 LUX

(b) Visual check of installed or partially exposed bearings (installed in housings or on shafts/gears/etc) is permitted. Sealed bearings are checked without closures (shield, seals) or enclosed lubricant (removed during cleaning).

目视检查安装的或部分暴漏的轴承(安装在壳体上或轴、齿轮等上) 是允许的。检查密封轴承时没有封闭剂(屏蔽罩、密封)或封闭润滑剂(清洁过程中拆除)。

CAUTION: WHEN HANDLING BEARINGS WHICH ARE CLEANED AND NOT OILED, WEAR EITHER SYNTHETIC RUBBER GLOVES OR NYLON MESH GLOVES WITH POLYETHYLENE PALMS AND FINGERS. IF NOT AVAILABLE, COTTON GLOVES SHALL BE WORN. DO NOT TOUCH BEARINGS WITH BARE HANDS.

注意:在处理干净的轴承或没有油封的轴承时,需要戴橡胶或尼龙手套,如不适用,可以戴棉布手套。不要光着手触摸轴承。

(c) Prior to cleaning demagnetize bearing so residual magnetism does not exceed five gauss.

在清洗之前,轴承退磁,使剩磁不超过5高斯。

(d) Prior to inspection, clean bearings per Method No. 203P.

在检查之前,按照方法203P检查轴承。

(e) Place bearings in a covered container or plastic bag to minimize contamination.

把轴承放在有盖的容器或所料袋中, 减少污染。

(f) Prior to test, lubricate bearing to be checked using filtered oil (MIL-L-6085) (SECTION VII).

在测试之前,用过滤的油液(MIL-L-6085)润滑检查后的轴承。

(g) Visually check bearing. Refer to Table 303.

按照表303目视检查轴承。

(h) Perform bearing analyzer check on non-separable bearing as follows:

按以下步骤对不能分离的轴承进行轴承分析仪检查。

NOTE: The following procedures apply only when using Bearing Analyzer (Electronic Bearing Analyzer). (Refer to Figure 318).

注:以下的步骤仅适用用轴承分析仪(电子轴承分析仪)。

Master Bearing is obtained from Bearing Inspection Inc., (SECTION VII).

主轴承从轴承检查公司获得(第七章节)。

Master Bearing is used to calibrate the analyzer in accordance with manufacturer instructions.

主轴承用于根据制造商的说明来校准分析仪。

(i) Bearing shall conform to limits in Figure 318 and Table 304.

轴承将符合图318,表304的限制。

(j) Dip bearing in oil (MIL-L-6085) (SECTION VII) heated to 120 to 140°F (49 to 60°C) for five minutes and allow to drain. Do not oil bearings used in pneumatic valves. For sealed bearings, replace enclosed lubricant and reinstall closures (shields, seals) per applicable manual.

将轴承浸入到油液(MIL-L-6085)中,加热到120 – 140°F(49-60°C )5分钟,然后排干。不要对使用在气动活门上的轴承进行油润滑。对于密封的轴承,更换密封的润滑剂,并根据适用手册重新安装密封盖(护罩、密封件)。

(k) Package bearing along with part number identification in heat sealable transparent plastic bag (MIL-B-22191D) (SECTION VI). Evacuate air from bag and heat seal shut.

把轴承包装在热密封透明塑料袋中,标识件号。确保塑料袋隔离空气。从袋子中排出空气,并热密封闭合。

|

Bearing Analyzer Figure 318 |

|

|

|

NOTES: 注: (1) BEARING ANALYZER EQUIPMENT CONSISTS OF THE FOLLOWING OR EQUIVALENT: 轴承分析仪包含以下设备。 -BEARING ANALYZER DRIVE UNIT MODEL BA-20-3D 轴承分析仪驱动装置BA-20-3D -BEARING ANALYZER INDICATOR UNIT MODEL BA-20-3E 轴承分析仪指示装置BA-20-3E -BEARING ANALYZER WHEEL CONTROL MODEL BA-20-3DC 轴承分析仪轮子控制BA-20-3DC -INTERFACE UNIT MODEL BA-96-2 接口BA-96-2 |

|

(2) GENERAL PROCEDURES (REFER TO ANALYZER MANUFACTURER INSTRUCTIONS FOR DETAILS): 通用程序(详参考分析仪制造商说明): -SELECTOR SWITCH SETTINGS FOR ANALYZER OPERATION 把开关设置为分析仪的工作状态 -SET MILLIVOLTS FULL SCALE SELECTOR TO 1 把毫伏满量程设置为1 -SET MILLIVOLTS PER DIVISION SELECTOR TO 1 把毫伏PER DIVISION设置为1 -SET MILLISECONDS PER DIVISION SELECTOR TO 10 把毫秒PER DIVISION设置为1 |

|

(3) ALL NON-SEPARABLE BEARINGS ARE TO BE INSPECTED WITH WEIGHTS INSTALLED ON THE BEARING. WEIGHTS PER GSE P/N 3737475-1 THRU -21 (OR EQUIVALENT) DETERMINED BY BEARING OD SIZE. REFER TO FIGURE 318A AND TABLE 305. 所有的不能分离的轴承都需要用安装在轴承上的砝码进行检查。砝码参照由轴承的外径决定的GSE件号 3737475-1 ~ -21(或等效物)。参见图318A和表305。 |

|

(4) NON-SEPARABLE BEARING NOISE INSPECTION ACCEPTANCE CRITERIA FOR NON SEPARABLE BEARING: 不可分离轴承的不可分轴承噪声检测验收标准 |

|

|

|

(5) REFER TO FIGURE 304 FOR OTHER NON-SEPARABLE BEARING CHECK REQUIREMENTS. 其他不可分离的轴承检查要求见图304。 |

|

Table 304. Non-Separable Bearing Check Requirements 不能分离的轴承的检查要求 |

||

|

Condition/Defect 状态/缺陷 |

Functional Surface Requirements 功能表面的要求 |

Non-Functional Surface Requirements 非功能表面的要求 |

|

Arcing 弧光 |

Not permitted 不允许 |

Not permitted 不允许 |

|

Bent 弯曲 |

Not permitted 不允许 |

Not applicable 不适用 |

|

Brinelling (true) 冲击腐蚀 |

Permitted if passes Bearing Analyzer Check. If not visible will be checked during Bearing Analyzer check. 允许通过轴承分析仪检查。如果不可见,将在轴承分析仪检查期间检查。 |

Not applicable. 不适用 |

|

Brinelling (false) 摩擦腐蚀 |

Permitted if passes Bearing Analyzer Check. If not visible will be checked during Bearing Analyzer check 允许通过轴承分析仪检查。如果不可见,将在轴承分析仪检查期间检查。 |

Not applicable. 不适用 |

|

Burnishing 擦亮 |

Permitted. If not visible will be checked during Bearing Analyzer check 允许。如果不可见,将在轴承分析仪检查期间检查。 |

Not applicable 不适用 |

|

Burrs 毛刺 |

Not permitted. If not visible will be checked during Bearing Analyzer check. 不允许。如果不可见,将在轴承分析仪检查期间检查。 |

No raised metal permitted. Use stone to remove raised metal. Defect size of 0.125 inch (3.17 mm) max. Permitted. 不允许凸起金属。用磨石除去凸起的金属。缺陷尺寸为0.125英寸 (3.17毫米)最大允许。 |

|

Corrosion 腐蚀 |

Not permitted. 不允许 |

If not visible will be checked during Bearing Analyzer check. Remove corrosion. Resulting defect size of 0.125 inch (3.17 mm) max. permitted. 如果不可见,将在轴承分析仪检查期间检查。清除腐蚀。产生的缺陷尺寸为0.125英寸(3.17毫米)最大允许。 |

|

Cracks(All components) 裂纹(所有组件) |

Not permitted. If not visible will be checked during Bearing Analyzer check. 不允许。如果不可见,将在轴承分析仪检查期间检查。 |

None permitted (visual check). 不允许(目测)。 |

|

Deformation Separator 变形分离 |

Silver-plate or Bronze Not permitted. 不允许镀银或青铜。 |

Not applicable. 不适用 |

|

Dents 凹痕 |

Permitted if passes Bearing Analyzer Check. If not visible will be checked during Bearing Analyzer check. 允许通过轴承分析仪检查。如果不可见,将在轴承分析仪检查期间检查。 |

No raised metal permitted. Use stone to remove. 0.125 inch (3.17 mm) max. Defect size permitted. 不允许凸起金属。用磨石除去。0.125英寸(3.17毫米)最大允许缺陷尺寸。 |

|

Discoloration (Heat) 热变色 |

Straw or brown color permitted. Red-purple, purple, blue permitted if RC 58 minimum is met when checked 3 places each on inner and outer races. 允许使用稻草色或棕色。允许红色、紫色、蓝色,但当在内圈和外圈各检查 3 处时,须符合 RC 58 的最低要求。 |

Straw or brown color permitted. Redpurple,purple, blue permitted if RC 58 minimum is met when checked 3 places each on inner and outer races. 允许使用稻草色或棕色。允许红色、紫色、蓝色,但当在内圈和外圈各检查 3 处时,须符合 RC 58 的最低要求。 |

|

Discoloration (Chemical) 变色(化学) |

Permitted. 允许 |

Not applicable. 不适用 |

|

Discoloration (Separator) Silver-plate or Bronze 变色(分离器) 镀银或青铜 |

Permitted. Must meet all other criteria. 允许.必须符合所有其他标准。 |

Permitted. 允许 |

|

Flaking, Peeling and Blistering of Plating 镀层剥落、剥落和起泡 |

Not permitted. 不允许 |

Not applicable. 不适用 |

|

Fractures 破碎 |

Not permitted. If not visible will be checked during Bearing Analyzer check. 不允许。如果不可见,将在轴承分析仪检查时进行检查。 |

Not permitted (visual check). 不允许(目视检查) |

|

Fretting/Fretting Corrosion 微振腐蚀 |

Not applicable. 不适用 |

Permitted if 30% or less of surface is affected. 小于30%的表面受影响是允许的 |

|

Galling |

Not permitted. If not visible will be checked during Bearing Analyzer check. 不允许。如果不可见,将在轴承分析仪检查期间检查。 |

No raised metal permitted. Use stone to remove. No transfer of metal is permitted. 不允许凸起金属。用磨石除去。不允许金属转移。 |

|

Installation Marks OD, ID and Faces 安装标志OD 、ID和面 |

Not applicable. 不适用 |

No raised metal permitted. Use stone to remove. 0.125 inch (3.17 mm) defect depth max. 不允许凸起金属。用磨石除去。0.125英寸(3.17毫米)缺陷最大深度。 |

|

Nicks 刻痕 |

Permitted if passes Bearing Analyzer Check. If not visible will be checked during Bearing Analyzer check. 通过轴承分析仪检查后允许。如果不可见,将在轴承分析仪检查期间检查。 |

No raised metal permitted. Use stone to remove. 0.125 inch (3.17 mm) defect size permitted. 不允许凸起金属。用磨石除去。允许0.125英寸(3.17毫米)缺陷尺寸。 |

|

Pits Races and Rolling Elements 坑 滚道和滚动元件 |

Permitted if passes Bearing Analyzer Check. If not visible will be checked during Bearing Analyzer check. 通过轴承分析仪检查后允许。如果不可见,将在轴承分析仪检查期间检查。 |

No raised metal permitted. Use stone to remove. 0.125 inch (3.17 mm) max. defect size permitted. 不允许凸起金属。用磨石除去。0.125英寸(3.17毫米)最大允许 缺陷尺寸。 |

|

Pits Separators Silver-plate or Bronze 银镀层或铜保持架上的麻点 |

Permitted 0.020 inch (0.51 mm) max. size. 允许0.020英寸(0.51毫米)最大尺寸。 |

Not applicable. 不适用 |

|

Rust 锈蚀 |

Not permitted (visual check). 不允许(目视检查)。 |

Remove rust. Resulting defect size of 0.125 inch (3.17 mm) max. permitted. 除锈。产生的缺陷尺寸为0.125英 寸(3.17毫米)最大允许。 |

|

Scoring 擦痕 |

Permitted if passes Bearing Analyzer Check. If not visible will be checked during Bearing Analyzer check. 允许通过轴承分析仪检查。如果不可见,将在轴承分析仪检查期间检查。 |

No raised metal permitted, use stone to remove. 0.125 inch (3.17 mm) resulting defect size permitted. 不允许金属凸起,用磨石去除。允许0.125英寸(3.17毫米) 的缺陷尺寸。 |

|

Scratches and Scuffs/ Rollers/Balls 划痕和擦伤/滚轴/滚珠 |

Permitted if passes Bearing Analyzer Check. If not visible will be checked during Bearing Analyzer check. 允许通过轴承分析仪检查。如果不可见,将在轴承分析仪检查期间检查。 |

Not applicable. 不适用 |

|

Scratches and Scuffs/ Inner/Outer Races 划痕和擦伤/内圈/外圈 |

Permitted if passes Bearing Analyzer Check. If not visible will be checked during Bearing Analyzer check. 允许通过轴承分析仪检查。如果不可见,将在轴承分析仪检查期间检查。 |

Not applicable 不适用 |

|

Silver-plate Flaking 银镀层剥落 |

Not permitted 不允许 |

Defects in plating from handling,adhesion testing, or balance stock removal is permitted 因处理、附着力测试或平衡料而造成的电镀缺陷允许清除 |

|

Silver-plate Discoloration 镀银的变色 |

Permitted.Silver-plate must meet all other criteria. 允许.镀银必须符合所有其他标准。 |

Permitted. 允许 |

|

Spalling 剥落 |

Not permitted. If not visible will be checked during Bearing Analyzer check. 不允许。如果不可见,将在轴承分析仪检查期间检查。 |

Not applicable. 不适用 |

|

Stains 色斑 |

Permitted. 允许 |

Permitted. 允许 |

|

Surface Slag Inclusions 表面夹渣 |

Not permitted. If not visible will be checked during Bearing Analyzer check. 不允许。如果不可见,将在轴承分析仪检查期间检查。 |

0.125 inch (3.17 mm) max. defect size permitted. 0.125英寸(3.17毫米)最大允许缺陷尺寸。 |

|

Varnishing 清漆 |

Permitted 允许 |

Permitted 允许 |

|

Wear 磨损 |

Checked with Bearing Analyzer. 轴承分析仪检查。 |

Permitted face, OD and ID within tolerance average. 允许的端面、外径和内径在平均公差范围内。 |

|

Wear Separator Silver-plate or Bronze 银镀层或铜保持架上的磨损 |

Permitted if silver-plate is worn through to parent material at rolling element and cage contact area. It cannot be more than 0.080 inch (2.03 mm) max. in size. 如果滚动体和保持架接触区域的银板已磨损至母体材料,最大尺寸不能超过 0.080 英寸(2.03 毫米),则允许使用。 |

Not applicable. 不适用 |

![图片[20]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-20.png)

![图片[21]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-21.png)

![图片[22]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-22.png)

![图片[18]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-18.png)

![图片[19]-SECTION III – INSPECTION 检查(二)之轴承检查-张群记事](https://www.aeroacm.cn/wp-content/uploads/2025/06/word-image-6941-19.png)